The anti-reflective coatings (also known as AR coatings) is to reduce or eliminate the reflection of light on optical surfaces such as lenses, prisms, and mirrors. This increases the amount of light transmitted through these elements and reduces or eliminates stray light in the system. AR coatings are widely used in various optical systems, optical lenses, and optical instruments to improve the clarity of images in optical systems and reduce glare caused by light reflecting back and forth.

The working principle of anti-reflective coatings is based on the interference of light. When light hits the surface of an optical element, part of the light is reflected, and part of it enters the element.

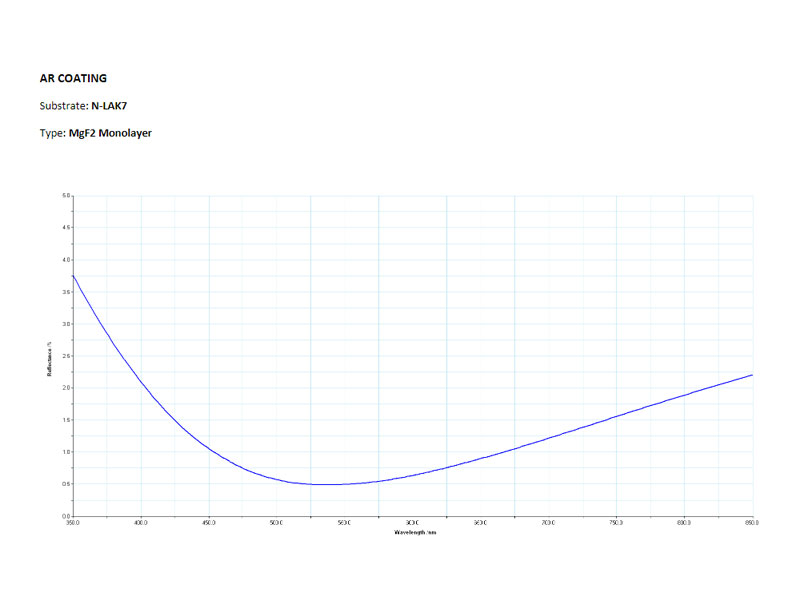

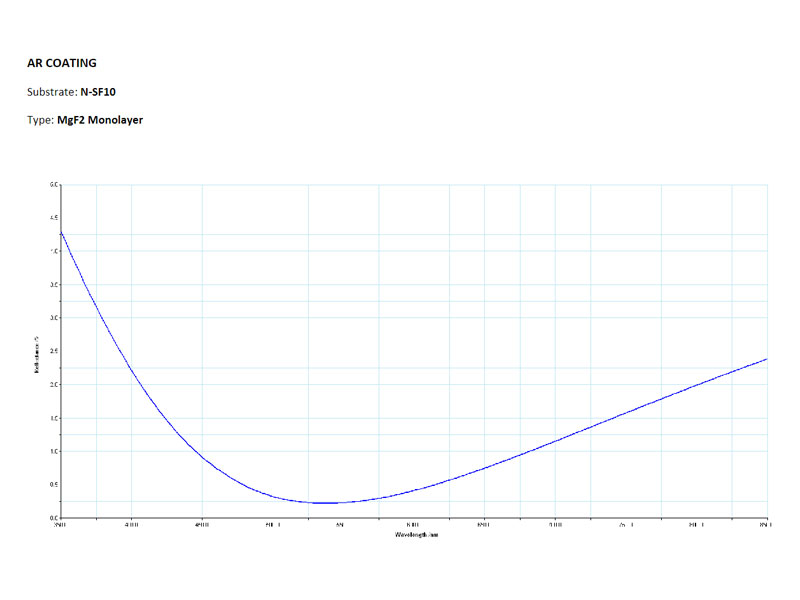

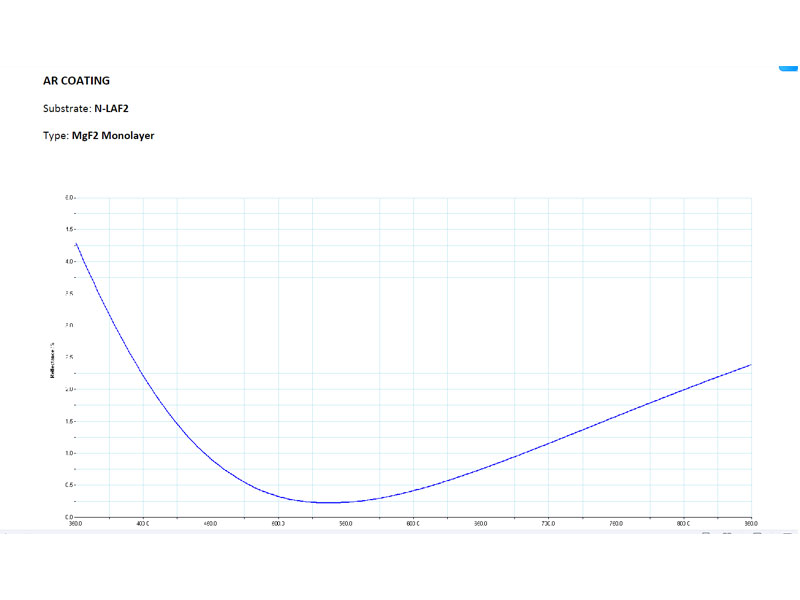

By coating the surface of the element with a thin layer of transparent dielectric material, the anti-reflective coating causes the light reflected from the front and back surfaces of the coating to interfere with each other, thereby reducing the reflected light and increasing the transmitted light. Specifically, when the thickness of the coating is equal to one-quarter of the wavelength of the incident light in the coating, the two reflected beams will cancel each other out, allowing more light to pass through the element.

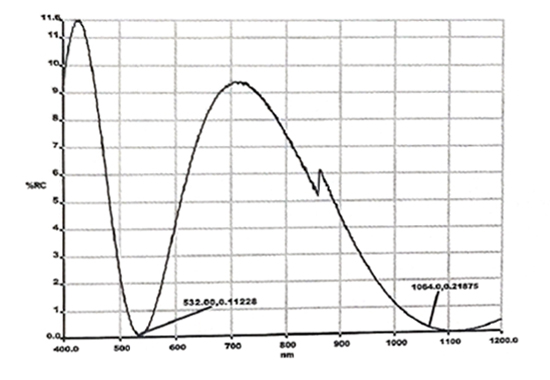

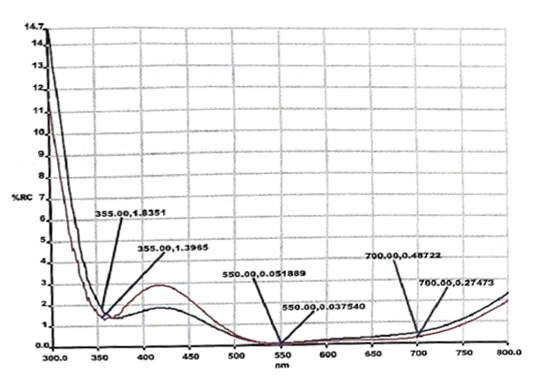

Dual Wavelength AR Coating

AR@532nm & 1064nm AR@355nm & 550nm-700nm

Anti-reflective coatings are widely used, especially in high-precision optical instruments such as telescopes and microscopes. These instruments typically consist of multiple lenses, where reflection losses can be significant.

By coating each lens surface with an anti-reflective coating, reflection losses can be effectively reduced, and light transmission can be increased. For example, modern optical sights often use multi-layer anti-reflective coatings, achieving light transmission rates of over 95%.