Silicon carbide is a very hard material similar to diamond, with good thermal conductivity and chemical stability. Silicon carbide mirrors take advantage of these properties of silicon carbide materials to achieve light reflection and focus.

Silicon carbide mirror is the core component of high-performance optical system, and its performance is very important to the observation effect.

Silicon scanning mirror is generally made of monocrystalline silicon material, which is a kind of high-performance optical element with excellent thermal stability and optical properties. Silicon scanning mirror is widely used in laser radar, optical measurement, laser processing and other fields.

Silicon scanning mirror is generally made of precision machining technology such as cutting, grinding and polishing, and has the characteristics of high precision and high surface finish. In LiDAR, the silicon scanning mirror can be used as a scanning element to complete the scanning and positioning of the policy by manipulating the direction of the reflected light. In optical measurement, the silicon scanning mirror can be used as a scanning or modulating element to complete the accurate control and measurement of the beam. In laser processing, the silicon scanning mirror can be used to control the power and beam shape of the laser to complete the precision machining of various materials.

The silicon scanning mirror is controlled by the direction of the reflected light to complete the scanning and positioning of the policy. Specifically, when the laser announces the laser beam, the beam hits the surface of the silicon scanning mirror and is reflected off through the effect of the mirror. By manipulating the rotation or translation motion of the silicon scanning mirror, the direction of the reflected beam can be changed, and then the scanning and positioning of the beam can be completed. In LiDAR, the scanning motion of the silicon scanning mirror can complete the 3D scanning and imaging of the surrounding environment, so as to complete the detection and positioning of the policy. In optical measurement, the scanning and modulation effects of the silicon scanning mirror can complete the accurate control and measurement of the light beam, so as to complete the measurement of the size, shape, spacing and other parameters of the object.

In short, the silicon scanning mirror completes the scanning and positioning of the policy by accurately manipulating the direction of the reflected light, providing a high-precision and high-reliability solution for a variety of applications.

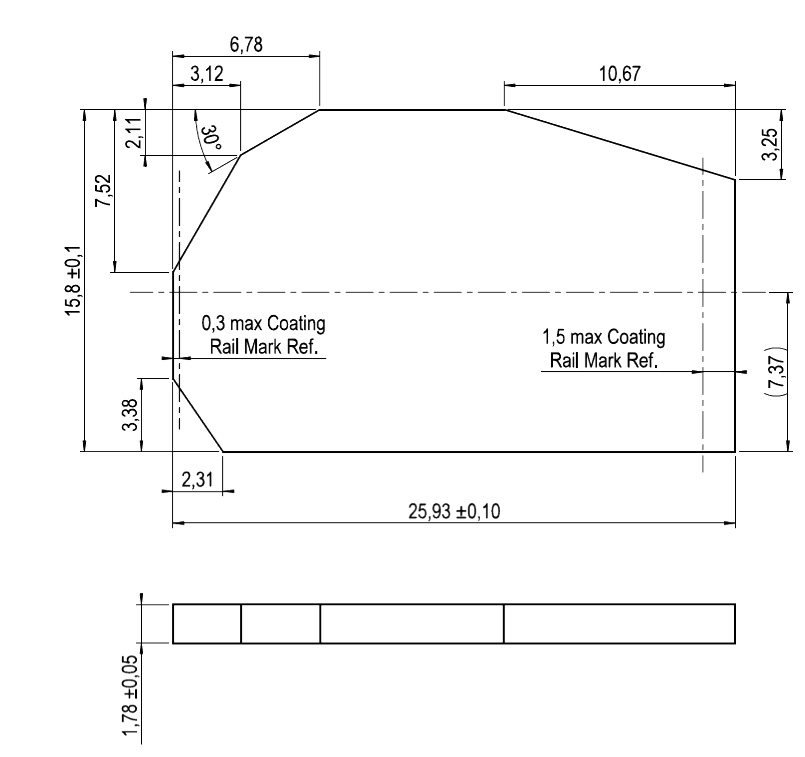

| Material | Si crystal P or N |

| Purity | 5N-9N |

| Crystal orientation | |

| Dimension tolerance | ± 0.02 / ± 0.1mm |

| Parallelism | Better than 3 arc min |

| Surface quality | 60/40 or better |

| Flatness: | λ/8@632nm |

| Dimension | Beam size |

| L * W * T (mm) | |

| 8.4x11.5x1.05 | 5 |

| 9x12x1.05 | 5 |

| 12.6x15x1.7 | 8 |

| 10.6x25.4x1.7 | 8 |

| 13.7x20.3x2 | 10 |

| 13.69x20.32x1.5 | 10 |

| 20x25x2 | 12 |

| 19x32x2 | 12 |

| 17.78x24.43x1.5 | 12 |

| 17.2x22.5x1.2 | 12 |

| 24.8x39.4x3.2 | 16 |

| 23x34x2 | 16 |

| 23x30x2 | 16 |

| 21x30x2 | 16 |

| 30x35x2 | 20 |

| 27x32x2 | 20 |

| 25x30x2 | 20 |

| 35x45x2 | 25 |

| 34x55x4 | 25 |

| 46.7x70.1x4 | 30 |

| 45x70x4 | 30 |

| 43x63x4 | 30 |

| 42x65x2 | 30 |

| 60x80x4 | 40 |

| 47x76x5 | 40 |