CVD ZnSe windows are made from zinc selenide (ZnSe) material synthesized through chemical vapor deposition (CVD). ZnSe is a yellow-transparent polycrystalline material known for its high purity, strong environmental adaptability, and ease of processing. It exhibits low optical transmission loss and excellent transmittance, making it particularly suitable for high-power laser systems.

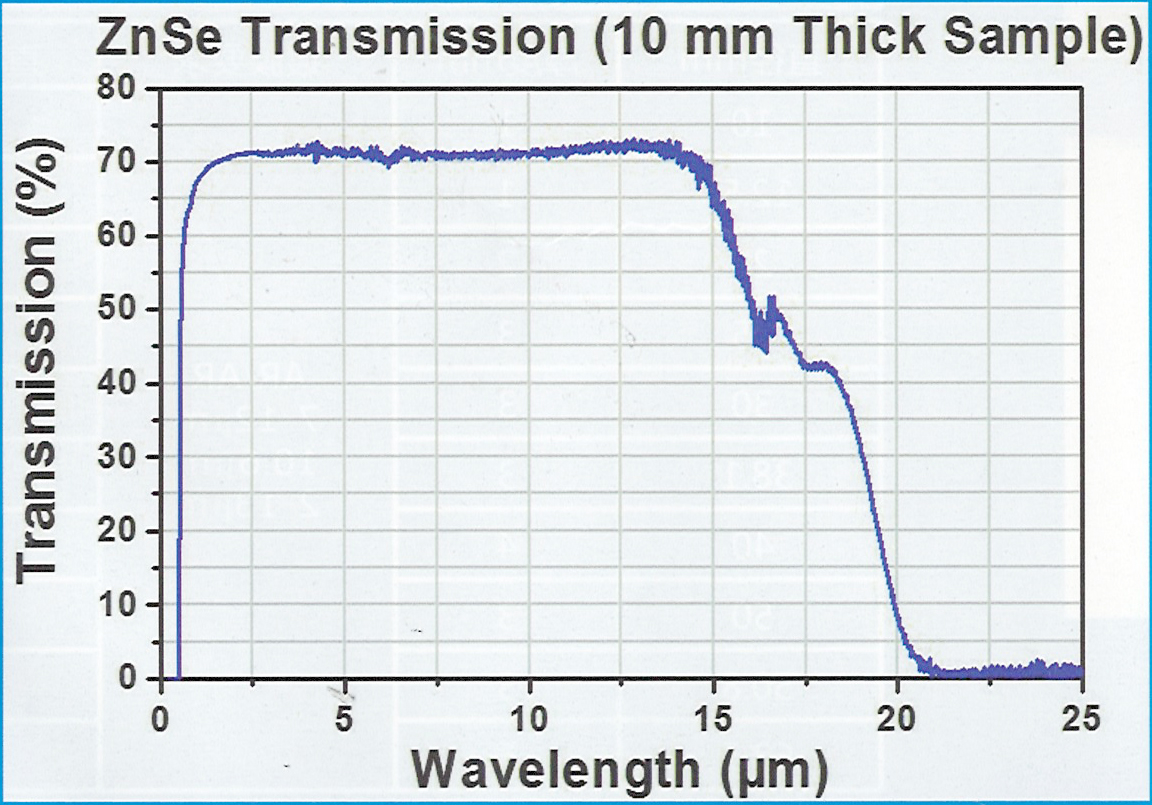

CVD ZnSe windows exhibit high transmittance in the 600 nm to 16 μm wavelength range, making them well-suited for infrared spectroscopy applications.

Material Characteristics:

High Purity: The material boasts high purity, strong environmental adaptability, and ease of processing.

Low Absorption: It features a low absorption coefficient of less than 0.0005 cm^-1 at a wavelength of 10.6 μm.

Thermal Shock Resistance: The material has excellent thermal shock resistance, making it ideal for high-power CO2 laser systems.

Low Hardness: Due to its relatively low hardness, ZnSe is prone to scratches and typically requires a high-hardness anti-reflective coating for protection.

| Physical characteristics | ||

| Density (@300K, g/cm³) | 5.27 | |

| Fusing point (K) | 1.798 | |

| Thermal conductivity @298K, J/(K *m*c) | 18 | |

| Coefficient of thermal expansion | @273K | 7.1*10-6 |

| 1/K | @373K | 7.8*10-6 |

| @473K | 8.3*10-6 | |

| Thermal capacity (@298K, J/(g*K) | 0.339 | |

| Hardness | Knoop, with 50g indenter, Kg/mm² | 120 |

| Vickers, with1kg indenter, kg/mm² | 112 | |

| Young's modulus (E), Gpa | 67.2 | |

| Bulk modulus (K), Gpa | 40 | |

| Surface elastic limit, mpa | 55.1 | |

| Optical characteristic | ||

| Thermo-optical coefficient (dn/dT) @1.06um @298-358K, 1/K | 6.1*10-5 | |

| Restrahlen peak, (mm) | 45.7 | |

| Reflection loss @10.6um (both surfaces). % | 29.1 | |

| Reflection inhomogeneity (dn/n) @0.633um, < | 3*10-5 | |

| Specifications | Commercial spec. | High precision spec. |

| Dimension | 5mm~350mm | |

| Dimension tolerance | ±0.1mm | ±0.05mm |

| Focal length tolerance | ±2% | ±1% |

| Surface quality | 60/40 | 40/20 |

| Centration | < 3 arc min | <1arc min |

| Surface figure | 3λ | 2λ |

| Surface irregularity | 1/4λ | 1/10λ |

| Clear aperture | >85% of dim | >90% of dim |

| Bevel | <0.2mm x 45deg | <0.1mm x 45deg |

| Coating | AR/AR 7-12um / 10.6um / 2-13um | |

| Material | Diameter (mm) | Thickness (mm) | Coating |

| CVD ZnSe | 12.7 | 2.4 | AR/AR 10.6um |

| CVD ZnSe | 12.7 | 2.5 | AR/AR 10.6um |

| CVD ZnSe | 19.05 | 2 | AR/AR 10.6um |

| CVD ZnSe | 20 | 2 | AR/AR 10.6um |

| CVD ZnSe | 20 | 3 | AR/AR 10.6um |

| CVD ZnSe | 25 | 3 | AR/AR 10.6um |

| CVD ZnSe | 38.1 | 3 | AR/AR 10.6um |

High-Power CO2 Lasers:

Due to its high purity, strong environmental adaptability, ease of processing, and low optical transmission loss, CVD ZnSe is the optimal window material for industrial high-power CO2 lasers.

Infrared Applications:

CVD ZnSe excels in infrared applications, making it suitable for thermal imaging, FLIR (Forward-Looking Infrared) systems, and medical systems. Its low absorption coefficient and high resistance to thermal shock make it widely used in these systems.

Military Equipment:

CVD ZnSe is also employed in advanced missile, aircraft, tank, and warship infrared search and targeting systems, serving as a key material for lenses, prisms, and other optical components.