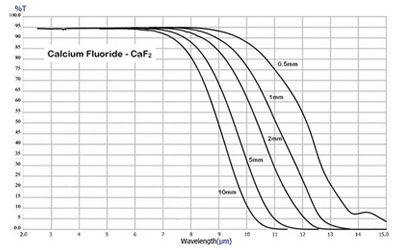

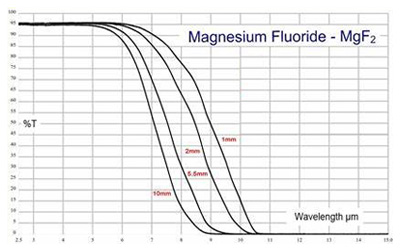

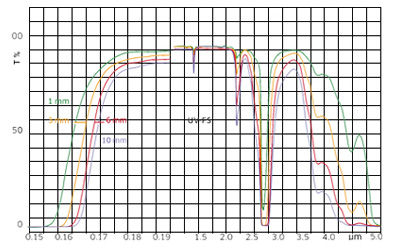

The primary materials for UV window panes include silicon dioxide (SiO2), sapphire (Al2O3), and magnesium fluoride (MgF2). These materials possess excellent UV light transmittance and high energy resistance, making them suitable for UV lasers. Additionally, UV window panes can undergo coating treatments to enhance their light transmission performance and durability.

Optical UV window panes are flat, parallel, transparent optical surfaces used to protect the internal optical components of UV lasers. They are designed to shield sensors and other electronic instruments from environmental conditions. UV laser window panes need to have characteristics such as high transmittance, high energy resistance, corrosion resistance, and stability to ensure efficient UV light transmission and protect the equipment from damage.

Specifically, the characteristics of optical UV window panes include:

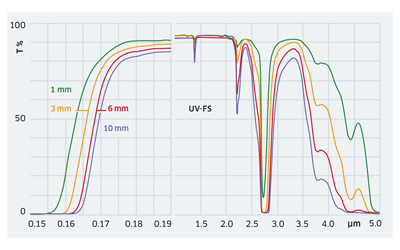

1. High Transmittance: UV laser window panes need to have high transmittance to ensure that as much UV light as possible can pass through the window, thereby improving the laser’s output efficiency and energy density.

2. High Energy Resistance: Since UV lasers have relatively high energy, the window panes need to withstand high-energy laser beams without damage or deformation.

3. Corrosion Resistance: UV lasers may use some highly corrosive media or materials, so the window panes need to have corrosion resistance to maintain their optical performance and lifespan.

4. Stability: The window panes need to maintain their optical characteristics and mechanical strength over long-term use, without being easily affected by external environmental conditions.

5. Chemical Stability: Materials like quartz glass have good chemical stability and are not easily corroded by acids, bases, and other chemical substances, thereby maintaining stable performance.

Specifications | Commercial spec. | High precision spec. |

Material | Quartz, Fused silica, CaF2, MgF2 | |

Dimension | 5mm~100mm | |

Dimension tolerance | ±0.1mm | ±0.05mm |

Surface quality | 60/40 | 20/10 |

Surface flatness | 1/4λ | 1/10λ |

Clear aperture | >85% of dim | >90% of dim |

Angel tolerance | 3 arc min | 5 arc sec. |

Parallelism | <1 arc min | <30 arc sec. |

Bevel | <0.2mm x 45deg | <0.1mm x 45deg |

Coating | Up on clients’ request | |