Fused silica galvo scanning mirrors are high-speed scanning devices that use fused silica as the substrate. They achieve precise laser beam control by driving two mirrors to rotate rapidly around vertical axes using electromagnetic coils. These scanning mirrors are widely used in laser marking, laser processing, and other applications.

The working principle of fused silica galvo scanning mirrors involves controlling the magnitude and direction of the current to generate a magnetic field that acts on magnets fixed around the coil, causing the mirrors to rotate around their axes. Computer-controlled current signals make the mirrors oscillate around the axis, changing the reflection angle and thus altering the direction and position of the laser beam. This design ensures system precision and scanning speed, making it suitable for high-precision marking and processing tasks.

Fused silica galvo scanning mirrors feature high precision, high speed, and excellent stability.

Key characteristics include:

1. High Precision: Utilizes high-quality fused silica substrates and all-dielectric high-reflective coatings to effectively reduce light scattering and improve reflection efficiency.

2. High Speed: Electromagnetic drive and negative feedback loop design ensure fast scanning speeds and high repeat positioning accuracy.

3. Stability: Robust mechanical design and material selection ensure long-term operational stability and reliability.

4. Fused silica galvo scanning mirrors are widely used in laser medical treatments, laser cosmetics, laser marking, and laser cutting. Due to their high precision and high-speed scanning capabilities, these scanning mirrors hold significant value in scientific research, industrial production, and medical equipment.

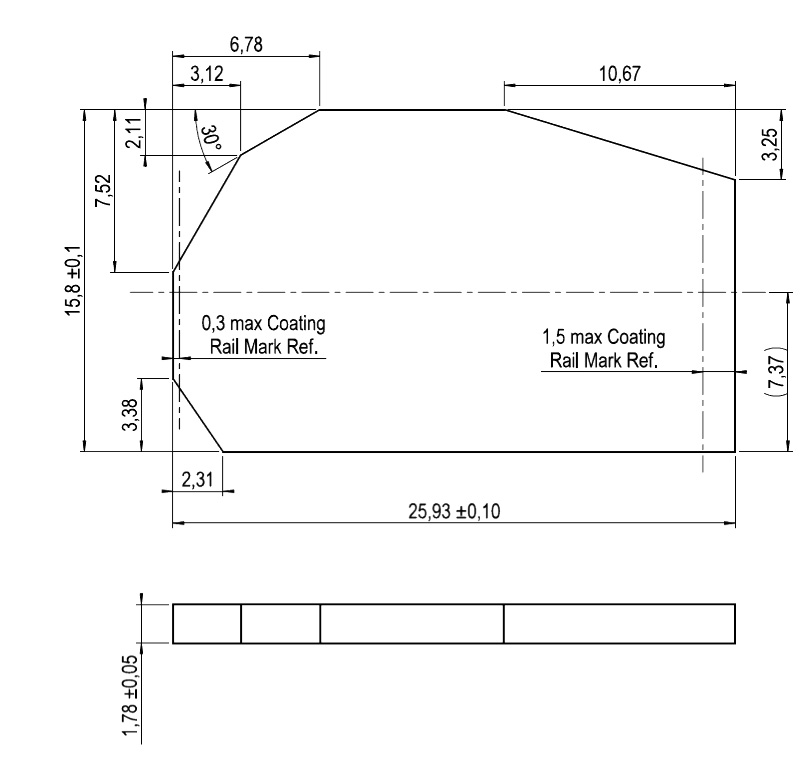

LXW Tolerance: | +0/-0.1 |

| Clear Aperture: | >90% |

| Thickness Tolerance: | +/-0.1mm |

| Surface Quality: | 40/20 |

| Surface Figure: | lambda/425mm2@632.8nm |

| Coating | |

| 266nm | Fused silica | Aluminum Reflector Coating |

| 1064nm/650nm/532nm | N-BK7 | Dielectric Reflector Coating |