Silicon carbide is a very hard material similar to diamond, with good thermal conductivity and chemical stability. Silicon carbide mirrors take advantage of these properties of silicon carbide materials to achieve light reflection and focus.

Silicon carbide mirror is the core component of high-performance optical system, and its performance is very important to the observation effect.

Improve the resolution

silicon carbide mirror has high specific stiffness and excellent thermal stability, these characteristics make it can obtain excellent image quality over a wide spectrum, thus greatly improving the resolution of the telescope or satellite

Material properties

As a new generation of optical mirror material, silicon carbide has high specific stiffness, high thermal conductivity, low thermal expansion coefficient and other excellent comprehensive properties, these characteristics make silicon carbide mirror in the environmental adaptability at the same time, can obtain excellent imaging quality in a wide spectrum.

Grind & Polishing

Bena Optics has several large rings - polishing machines and the know-how to overcome the hard surfaces of SiC. Compared with the ordinary optical polishing equipment, it is not only fast but also stable. Optical components for sale from the professional manufacturer now!

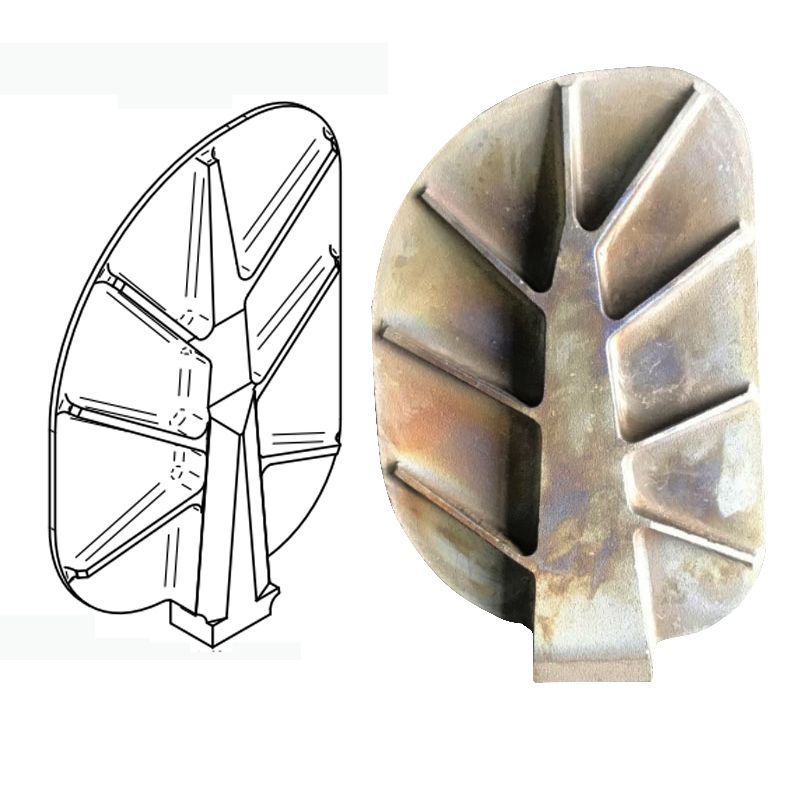

Light weight

Bena Optics uses an advanced CNC machining center for lightweight processing, the whole process is designed by computer and can be designed and processed at multiple levels according to customer requirements.

Coating

Usually metal coating, covering aluminum, silver, gold. Mainly depends on the customer's requirements, from UV to deep infrared can be met.

Quality control

1. Dimension measurement: using CMM to ensure the accuracy of component measurement, and the perfect size.

2. Surface accuracy: Using laser interferometer was used to detect the surface flatness.

3. Coating measurement: Use an advanced spectrophotometer.

Size (mm) | Upon customers’ request |

Clear aperture | >95% of Dim |

Surface quality | 40/20 laser quality |

Surface figure | Better than λ/2 @632.8nm |

Reflected Wavefront Error | λ/10 PV @ 632,8nm |

Light weight | Upon customers' request |

Coating | 355nm, 532nm, 1064nm, 1080nm, Gold, Silver, or customized |

Damage Threshold | 10ns pulse: 400MW/C㎡; |

CW:500W/C㎡ at 10.6μm typica |

The SiC scanning mirror plays an important role in laser processing . The optical path design of scanning galvo mirror systems has an important influence on the quality and efficiency of laser processing. A galvanometer usually consists of a parallel plate, one of which is plated with a reflective material, called a mirror. Behind the mirror, there is a flat plate as a reference whose position can be controlled by an electric field. The two ports of the galvanometer are connected to an external power source to create an electric field. When the electric field is applied to the galvanometer, the strength of the electric field will directly affect the displacement and Angle of the galvanometer, so as to change the direction of the beam and realize the reflection or refraction of the beam .

Application of silicon carbide galvanometer in laser processing

Beam shaping system: the laser beam needs to pass through the beam shaping system, so that the energy of the laser beam after shaping is approximately distributed in the flat top, so as to obtain uniform quenching effect on the surface of the machined material .

Transmission fiber and QBH head : these components play a role in laser processing to transmit and focus the laser beam, ensure the effective use of laser energy .