An achromatic cemented lens is a type of lens made from two different types of optical glass, typically crown glass and flint glass, cemented together. The purpose of this lens design is to correct chromatic aberration, allowing light of different wavelengths to converge at the same focal point, thereby improving image quality. Achromatic lenses are widely used in various optical systems, such as objective systems, imaging systems, and laser measurement systems.

There are various types of achromatic lenses, including doublet lenses, triplet lenses, and aspheric achromatic lenses. The doublet lens is the most common type, consisting of a positive lens made of low-refractive-index crown glass and a negative lens made of high-refractive-index flint glass. Triplet lenses further increase the nuCmber and complexity of lenses to optimize more optical characteristics. Aspheric achromatic lenses, on the other hand, incorporate aspheric designs on top of traditional achromatic lenses, further enhancing image quality and resolution.

Achromatic cemented lenses have a wide range of applications, primarily in the following fields:

1. Photography Lenses: Achromatic lenses are widely used in various photography lenses to ensure accurate color reproduction and reduce chromatic aberration under different lighting conditions.

2. Microscopes: Using achromatic lenses in microscopes can provide higher clarity images, making them suitable for scientific research and industrial inspection.

3. Telescopes: The application of achromatic lenses in telescopes can improve the clarity and color fidelity of long-distance observations, making them suitable for astronomical observations and long-distance monitoring.

4. Other Optical Systems: Achromatic lenses are also used in various optical systems that require high-precision imaging, such as rangefinders and spectrometers, to ensure measurement accuracy and reliability.

Specifications | Commercial spec. | High precision spec. |

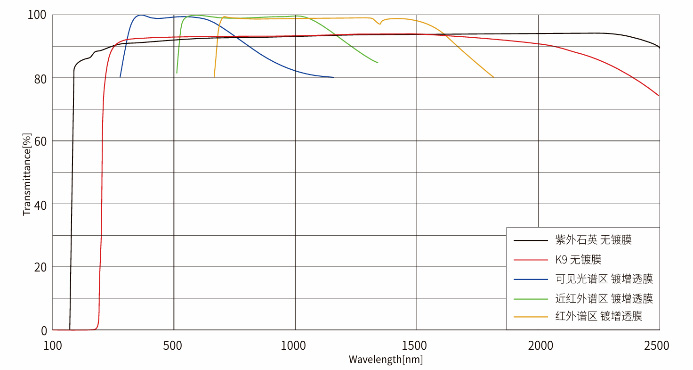

Material | UV glass (quartz, fused silica) | |

VIS glass (Schott, CDGM, HOYA, etc.) | ||

Diameter | Ø5mm~Ø600mm | |

Diameter tolerance | ±0.1mm | ±0.05mm |

Focal length tolerance | ±2% | ±1% |

Surface quality | 60/40 | 40/20 |

Centration | < 3 arc min | <1arc min |

Surface figure | 3λ | 2λ |

Surface irregularity | 1/4λ | 1/10λ |

Clear aperture | >85% of dia | >90% of dia |

Bevel | <0.2mm x 45deg | <0.1mm x 45deg |

Coating | Up on clients’ request | |

Type No. | Diameter | Focal length | Edge thickness | Center thickness | Back focal length | Centration |

φD( mm) | f( mm) | Te( mm) | Tc( mm) | fb( mm) | (') | |

ACL-10-20 | 10 | 20 | 5.1 | 6.7 | 16.6 | <1 |

ACL-10-50 | 10 | 50 | 4.4 | 5.0 | 47.5 | <1 |

ACL-12.7-50 | 12.7 | 50 | 4.7 | 5.7 | 47.3 | <1 |

ACL-12.7-100 | 12.7 | 100 | 4.3 | 4.8 | 97.9 | <1 |

ACL-15-25 | 15 | 25 | 6.0 | 8.8 | 20.7 | <1 |

ACL-15-50 | 15 | 50 | 5.0 | 6.3 | 47.1 | <1 |

ACL-20-50 | 20 | 50 | 5.7 | 8.1 | 46.0 | <1 |

ACL-25-50 | 25 | 50 | 7.1 | 10.9 | 44.9 | <1 |

ACL-25.4-50 | 25.4 | 50 | 7.0 | 10.9 | 44.9 | <1 |

ACL-25.4-80 | 25.4 | 80 | 6.1 | 8.5 | 75.9 | <1 |

ACL-25.4-100 | 25.4 | 100 | 5.8 | 7.7 | 96.5 | <1 |

ACL-25.4-200 | 25.4 | 200 | 5.1 | 6.1 | 197.0 | <1 |

ACL-40-100 | 40 | 100 | 8.9 | 13.7 | 92.8 | <1 |

ACL-40-200 | 40 | 200 | 7.2 | 9.6 | 194.8 | <1 |

ACL-50-100 | 50 | 100 | 2.3 | 19.9 | 90.0 | <1 |

ACL-50-200 | 50 | 200 | 9.6 | 13.3 | 193.3 | <1 |

ACL-50.8-200 | 50.8 | 200 | 9.5 | 13.3 | 193.3 | <1 |