Lightweighting of optical components refers to the use of new materials, new processes, and new design methods to reduce the weight of optical components as much as possible while ensuring performance. This approach has wide applications in fields such as aerospace, military, and medical, and can significantly reduce the overall weight and cost of systems, improving their portability and efficiency.

With the rapid development of space optical technology, the resolution of space optical remote sensor has been improved, and the aperture of reflective space optical primary mirror is required to increase continuously. Lightweight design, analysis and manufacturing of large aperture space optical mirror has become an indispensable key support technology active in the forefront of modern science and technology.

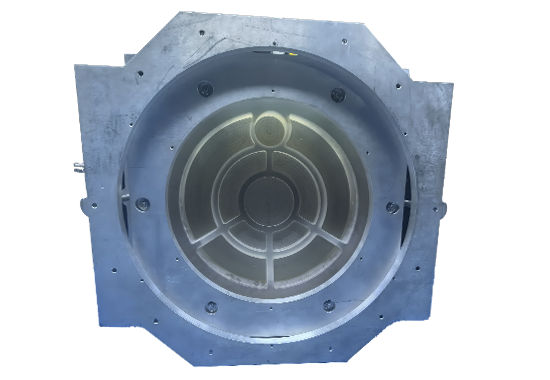

Bena Optics is a Zerodur commonly used for space optical mirrors. SiC and fused quartz for lightweight processing, to apply to the space ultra-low temperature environment of elliptical plane mirror as an example, CAD optimization lightweight structure, finite element analysis, flat light mirror in the state of self-weight mirror deformation is 0.014λ(rms), in the ultra-low temperature -150℃ environment mirror deformation is 0.002λ(r) ms), the numerical control system in the graphic way to control the actual lightweight machining, using chemical methods to eliminate the stress and micro cracks generated in the process of machining, the final surface shape accuracy of 0.022λ(rms).

Bena Optics specializes in lightweight optical components, primarily large-diameter aspheric mirrors and flat mirrors.

Materials: Zerodur, SiC, aluminum, and other high-hardness optical substrates.

Processing Methods: Mechanical drilling and weight reduction method. Using large CNC machining centers, mechanical rotation of the drill bit and abrasive mechanical grinding of the glass are employed to gradually form blind holes at the bottom of the mirror, achieving weight reduction.

Processable Sizes: Ø100mm to Ø800mm.

Lightweight Rate: 70%. The lightweight structure adopts a fan-shaped design or a customer-specified design, with hole wall thicknesses of 5mm or less.

Surface Error Monitoring: Using interferometers to monitor surface error, with local deviation RMS ≤ λ/100.

Lightweight Design: By using new materials and optimized designs, the weight of optical components can be significantly reduced. For example, the thickness of meta-lenses can reach the nanometer to micrometer scale, making them extremely lightweight and suitable for applications with strict weight requirements.

Simplified Structure: Lightweight designs often come with simplified structures, reducing complex components and connections, making the overall system more compact and efficient.

Cost Reduction: Lightweight designs usually lead to lower production costs, especially in mass production. For instance, meta-lenses produced using semiconductor processes have lower costs.

High Performance: Lightweighting does not sacrifice performance; instead, it improves the performance of optical systems through optimized designs. For example, lightweight mirrors can maintain large apertures while enhancing resolution and stability.

Strong Adaptability: Lightweight optical components are suitable for various fields, such as mobile devices and aerospace, significantly reducing energy consumption and improving the portability of equipment.

Improved Portability: Lightweight optical components can significantly reduce the overall weight of products, thereby enhancing the portability of devices. For example, meta-lenses with thicknesses reaching the nanometer to micrometer scale are extremely lightweight, making them suitable for applications with stringent space requirements. Additionally, lightweight designs help reduce energy consumption, as lighter devices require less power to operate, thereby extending battery life.

Simplified Design and Manufacturing Process: Lightweight optical components can simplify the design and manufacturing process of devices. Traditional lens assemblies often require complex lens systems to achieve optical performance, whereas lightweight designs can integrate more functions into fewer components, reducing the complexity and size of the product. This simplification not only lowers manufacturing costs but also increases production efficiency.

Market Competitiveness: Lightweight optical components have higher market competitiveness. Since lightweight designs often use advanced manufacturing processes, such as semiconductor processes, the cost of mass-produced optical components is lower. This makes them more attractive in fields such as consumer electronics, security surveillance, and automotive electronics.