Customized ultra-high precision optical components, covering aspheric surfaces, lightweight designs, coatings, and more.

Leveraging internationally leading processing equipment and technology.

Providing technical support starting from the design phase.

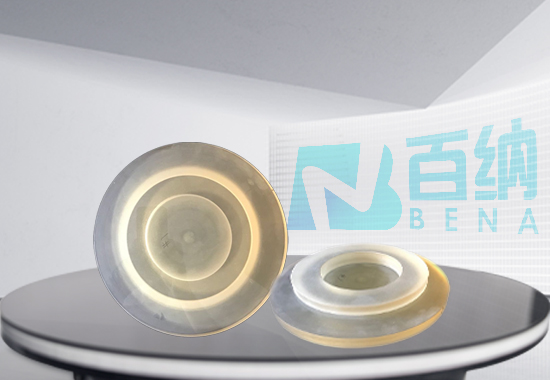

In addition to common optical materials, we primarily process SiC ceramic materials, Zerodur, and metals such as aluminum.

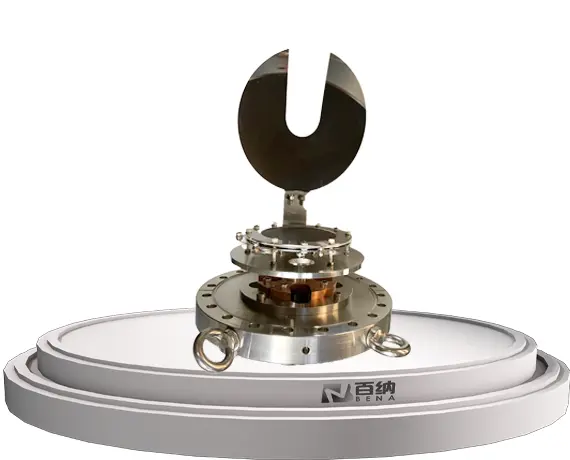

Lightweighting involves strategically removing material from optical components, typically using mechanical methods. This achieves a lighter structure while maintaining optical performance. By using low-expansion ceramics and glass, these structures maintain excellent optical performance and rigidity, while minimizing size, weight, and power consumption.

Bena Optics specializes in the manufacturing of the most challenging precision optical components, tirelessly developing ultra-precision, large-aperture, and lightweight optical elements. We excel in custom optical components of various shapes.

Bena Optics uses a Hitachi spectrophotometer for coating testing, covering a range of 180nm to 2900nm.