An alignment cube is a precision optical component whose unique structural design and manufacturing accuracy play a crucial role in the development of spacecraft. This regular hexahedron not only possesses exceptional geometric stability, but the angular error between its adjacent faces is typically controlled within a very narrow range, usually between 2 to 5 arcseconds. More importantly, 3 to 5 adjacent faces of the alignment cube are coated with reflective films and crosshair markings, making it an indispensable part of spacecraft development.

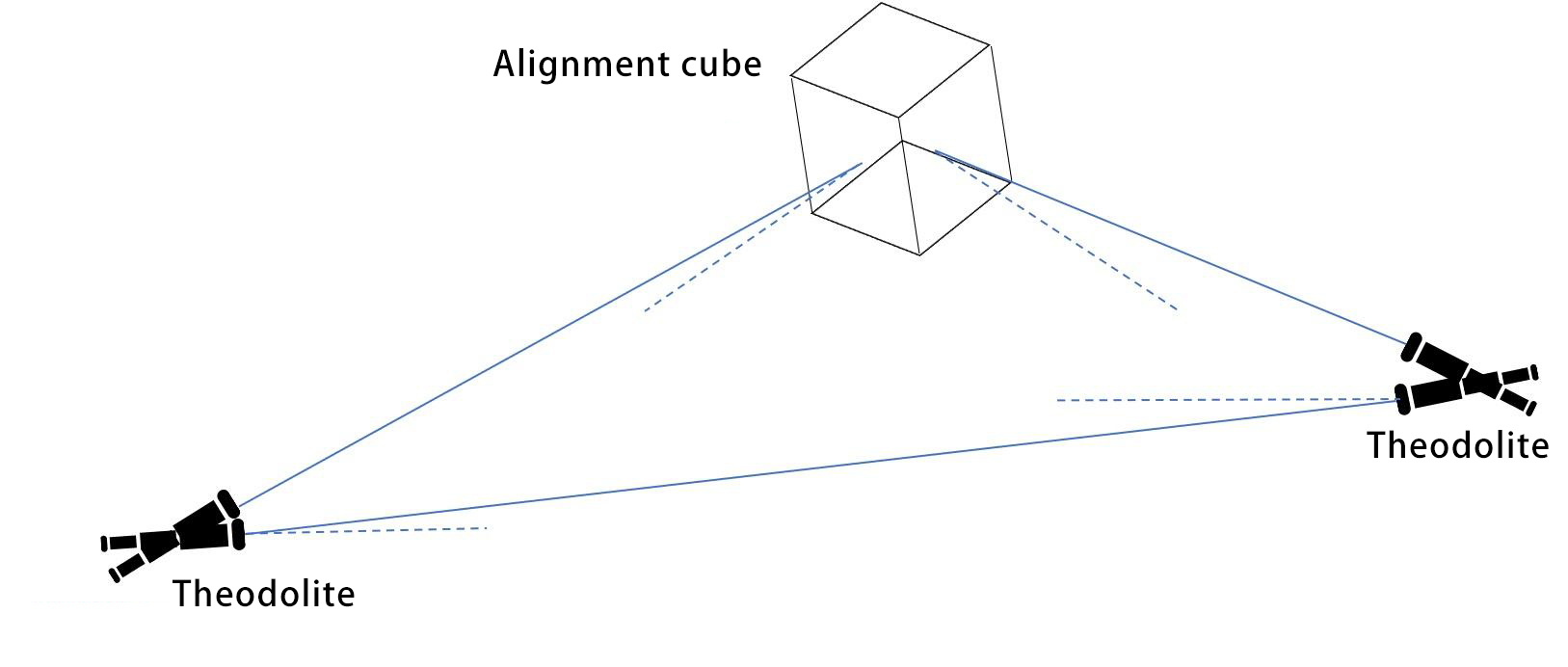

In the manufacturing and testing of spacecraft, precise measurement and positioning are key. Every component of the spacecraft needs to be accurately placed in three-dimensional space to ensure the overall system’s performance and stability. The optical alignment cube is an essential tool for achieving this goal. By using an electronic theodolite to measure the normal of the alignment cube’s reflective surfaces, a precise cubic mirror coordinate system can be constructed. This coordinate system not only represents the spatial position of the product but also provides an accurate reference for subsequent assembly and testing.

The application of alignment cubes in spacecraft development is not limited to constructing coordinate systems. Due to their high stability and precise reflective properties, they can also be used in the spacecraft’s attitude measurement and control systems. By monitoring the light beams reflected by the alignment cube, the spacecraft’s attitude and position can be accurately determined, providing critical information for navigation and control.

Furthermore, alignment cubes have extensive applications in the optical systems of spacecraft. Due to the presence of reflective films and crosshair markings, they can be used as mirrors or beam splitters in optical systems. This makes alignment cubes crucial components in the optical systems of spacecraft, providing precise optical elements for imaging, detection, and communication tasks.

However, the manufacturing and application of alignment cube also face some challenges. Firstly, due to their complex structure and high precision requirements, the manufacturing process demands extremely high technical expertise and stringent quality control. Additionally, given the harsh working environment of spacecraft, alignment cubes need to possess exceptional stability and durability. This requires manufacturers to exercise strict control over material selection, process design, and quality assurance.

In summary, alignment cubes play a vital role in the development of spacecraft. They not only provide precise references and coordinate systems for the manufacturing and testing of spacecraft but also play key roles in attitude measurement, optical systems, and control systems. As space technology continues to advance, the application of alignment cubes will continue to expand and optimize, providing more precise and reliable support for future space exploration.

In the future, as space technology progresses and spacecraft become increasingly complex, the requirements for the precision and stability of alignment cubes will also rise. To meet these demands, manufacturers need to continuously improve manufacturing processes and material selection to enhance the performance and quality of alignment cubes. Meanwhile, researchers need to explore new application areas and technological innovations to further expand the scope and depth of alignment cube applications in spacecraft development.

Moreover, as spacecraft missions become more complex and diverse, alignment cubes will need to adapt to a wider range of working environments and mission requirements. For instance, in deep space exploration missions, spacecraft face more complex and harsh environmental conditions, necessitating alignment cubes with higher radiation and temperature resistance. In manned space missions, the comfort and safety requirements of spacecraft are higher, requiring alignment cubes to incorporate more human-centric and safety considerations in their design and manufacturing.

In conclusion, as a critical component in spacecraft development, alignment cubes have broad application and development prospects. With continuous technological advancements and increasingly complex spacecraft missions, alignment cubes will play an even more significant role in future space exploration. Simultaneously, optical components company and researcher must continuously strive and innovate to meet the higher demands and expectations for alignment cubes in spacecraft development.