As a global optical components company of high-end optical solutions, we specialize in the research, development, and intelligent manufacturing of customized ultra-high precision optical components. Our product matrix includes:

Leveraging German ultra-precision lathes (accuracy <50nm) and an array of interferometers, we have established a comprehensive process system from conceptual design (Zemax/CodeV collaboration) and prototype trial production to mass production. Certified by ISO10110 standards, we have delivered over 3000 customized optical modules for cutting-edge fields such as quantum communication and EUV lithography machines, achieving manufacturing breakthroughs with optical surface precision of PV value <λ/20 and RMS <λ/100.

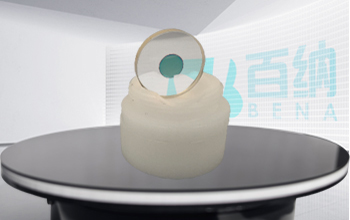

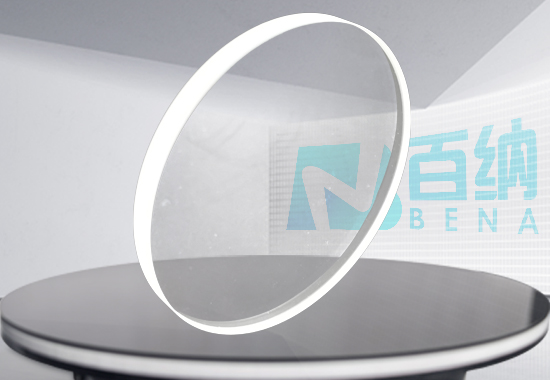

High-order aspheric lenses, utilizing freeform surface processing technology to effectively eliminate aberrations such as spherical and coma, achieving an ultra-high numerical aperture (NA) greater than 0.9.

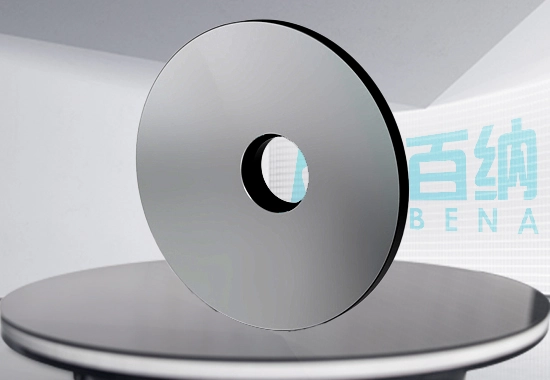

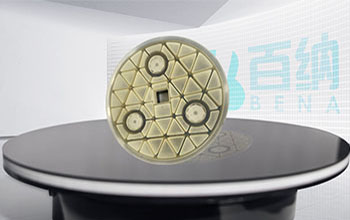

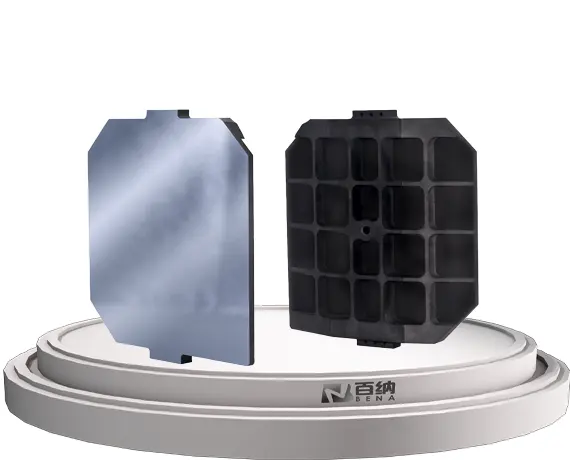

Topology-optimized lightweight components, achieving a 30%-50% mass reduction through finite element simulation, suitable for satellite payloads and LiDAR systems.

Nano-scale functional coatings, employing magnetron sputtering and ALD (Atomic Layer Deposition) technologies to provide anti-reflective, high-reflective, and beam-splitting coatings across the UV to terahertz spectrum, with a damage threshold of 10J/cm²@1064nm.

Large CNC machining centers.

Grinding and mechanical polishing are used, with polishing done via CCOS and surface correction by IBF and MRF.

Polishing is done using a ring polishing machine, with extended grinding to ensure a good surface profile for SiC.

SiC mirrors primarily accept metal coatings such as Al, Ag, and Au.

Ultra-high precision optical components China can be processed from Ø50mm to Ø1200mm.