Lasers are common optical devices widely used in fields such as laser communication, medical equipment, lighting, and laser printing. In practical applications, it is sometimes necessary to adjust the laser, such as changing the shape of the laser or adjusting the light intensity distribution. This operation is known as laser shaping.

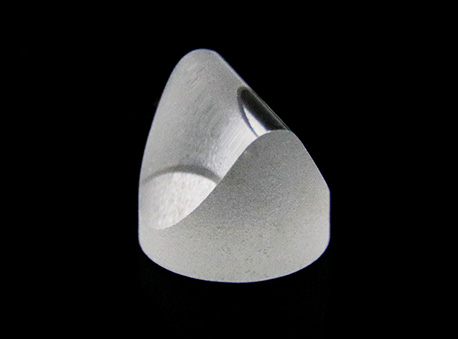

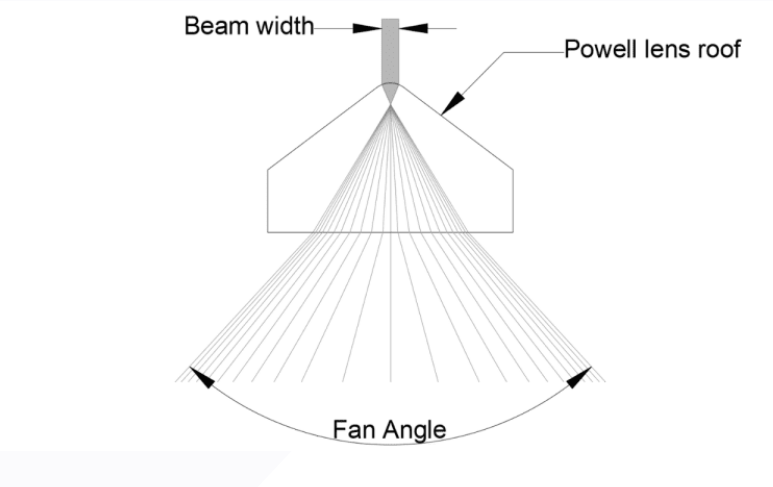

A Powell lens is a common laser shaping optical element designed to convert a circular spot into a linear spot and change the light intensity distribution. This process transforms the Gaussian distribution of light into a uniform energy beam, also known as a flat-top beam. A Powell lens is essentially a cylindrical lens with an aspheric surface, meaning that one direction of the surface has an aspheric distribution while the perpendicular direction has no curvature. Light entering the Powell lens converges and diffuses in one direction, while the spot length in the other direction remains unchanged. In the converging and diffusing direction, the degree of deflection of the light varies with the height of the incident pupil, thereby redistributing the light. Although ordinary cylindrical lenses can also output linear beams, they cannot change the light intensity distribution. When a Gaussian beam passes through an ordinary cylindrical lens, the resulting linear beam has very strong energy in the middle, gradually decreasing from the center, leading to poor uniformity.

In addition to producing a uniform linear beam, Powell lenses can also be used with other components to achieve different laser shaping effects. For example, two vertically placed Powell lenses can convert a circular spot into a square spot. Powell lenses have important applications in biomedicine, automotive assembly, and food processing.

Two main parameters influence the design of Powell lenses: fan angle and incident spot size. The fan angle refers to the angle at which the beam passes through the Powell lens and opens into a fan shape. Clearly, the larger the fan angle, the longer the linear beam obtained at the same distance.

The size of the incident spot is another important parameter affecting the design of Powell lenses. For lasers with a Gaussian distribution, the incident spot size refers to the diameter of the spot when the energy drops to 1/e² of the peak value. Generally, a specific Powell lens is only suitable for incident beams of corresponding sizes. If the beam size does not match, the energy distribution of the outgoing beam will be significantly affected.

Machine Vision: Powell lenses are widely used in machine vision applications, such as product defect detection, dimension measurement, and alignment.

Flow Cytometry: Powell lenses are used in flow cytometry instruments to measure the size and shape of cells and particles.

Laser Printing: Powell lenses are used in laser printers to produce high-quality barcodes and other markings.

Optical Measurement: Powell lenses are used in optical measurement instruments to measure the smoothness and roughness of surfaces.