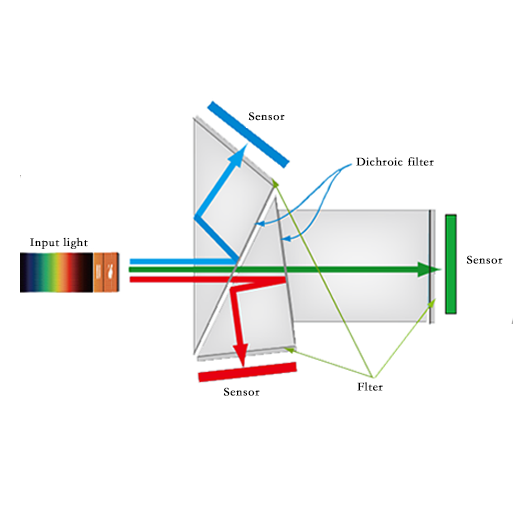

Prism cameras leverage prism-based light splitting technology to distribute incident light into different channels. Each channel’s image can achieve pixel-level alignment accuracy during motion or from different measurement angles. In prism-based cameras, the prism block consists of hard dichroic coatings, which essentially function as interference filters. These filters are responsible for the primary separation of the incident light.

Reflective Prisms: Reflective prisms operate based on the laws of reflection and refraction. When light reflects within the same medium, the angle of reflection equals the angle of incidence. When light enters another medium perpendicularly, it does not refract. Using a single reflective prism can reduce the amount of returned light received by the instrument. In practical applications, multiple reflective prisms are used for long-distance measurements.

Deflecting, Rotating, and Shifting Prisms Prisms that deflect the light path or shift the image from its original axis are beneficial in many imaging systems. Light is typically deflected at angles of 45°, 60°, 90°, and 180°. This helps in adjusting the system size or the light path without affecting the rest of the system setup. Rotating prisms, such as Dove prisms, are used to rotate inverted images. Shifting prisms maintain the direction of the light path while adjusting its relationship to normal.

Polarizing Prisms Common variants include the Glan-Foucault polarizer, made from two identical calcite prisms cut with edges parallel to the optical axis and mounted with a small air gap. This prism is transparent over a wavelength range from approximately 230 nm in the ultraviolet spectrum to over 5000 nm in infrared radiation. This broad wavelength transmission range makes the Glan-Foucault prism useful in various instruments. Like the Nicol prism, incident light striking the Glan-Foucault prism is divided into ordinary and extraordinary waves vibrating parallel or perpendicular to the optical axis. However, in this case, the divided light waves travel through the prism without refraction until they encounter the glass/air interface, where the ordinary light undergoes total internal reflection, while the extraordinary light passes through the boundary with only slight deviation.

Dispersive Prisms The dispersion of a prism depends on its geometry and the refractive index dispersion curve of the prism substrate. Small deflection angles determine the small angle between the incident and projected light. Green light deviates more than red light, and blue light deviates more than both red and green; red is typically defined as 656.3 nm, green as 587.6 nm, and blue as 486.1 nm.

Multispectral prism cameras by the optical prism manufacturer can split incident light and project it onto two different sensors, simultaneously performing visible light and near-infrared (NIR) inspections: one for the visible light color channel (wavelength 400-700 nm) and the other for the NIR channel (wavelength 750-900+ nm). This feature allows a single camera to inspect visible elements, subsurface defects, or other information detectable at NIR wavelengths. Multispectral cameras are ideal for inspecting banknotes, textiles, circuit boards, and organic products like fruits and vegetables.

Spectral prism imaging involves using a prism to decompose an incident composite light beam into multispectral beams or change the beam direction, then capturing images with different spectral or dynamic ranges using multiple sensors. The advantage of this technology is that it eliminates the need for “spatial compensation” of sensors when the camera and the surface are being photographed form a certain angle. Even when photographing rough surfaces, there is no “parallax” issue across multiple sensors. Imaging systems built with this technology are easy to install, highly accurate, cost-effective, and can completely replace multi-camera imaging solutions. Prism spectral imaging technology provides effective detection means for inspecting semiconductor wafers, fruits, vegetables, food, and packaging materials.

Prism cameras split the spectral range from visible light to short-wave infrared (SWIR) bands, performing spectral separation within the visible and SWIR bands or within the SWIR band alone.

Prism technology can split incident light into RGB wavelengths and project them onto high-precision configured CCDs. Therefore, prism cameras offer high-precision color reproduction, high spectral sensitivity based on wavelength separation (low color mixing), and can output extremely high-precision color image data and high dynamic HDR images. They also provide high spatial resolution for precise edge detection and can identify fine details of the inspection target.

Based on these characteristics, prism cameras are widely used in inspecting fruits, vegetables, coins, banknotes, textiles, plastics, LEDs, welds, glass, solar panels, industrial furnaces, and heated metals.

In conclusion, prism cameras, with their advanced light splitting and imaging capabilities, offer unparalleled precision and versatility in various industrial and scientific applications. Their ability to provide high-resolution, multispectral, and accurate color images makes them indispensable tools in modern machine vision systems.