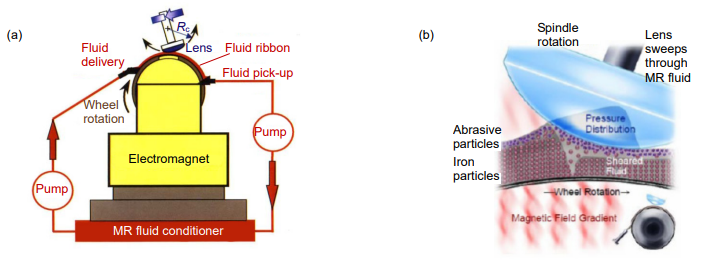

Magnetorheological Finishing (MRF) is an innovative processing technology that integrates theories from electromagnetism, analytical chemistry, and fluid dynamics. Its “polishing head” is formed by magnetorheological fluid (MR fluid) undergoing rheological changes in a gradient magnetic field, resulting in a “flexible polishing mold” with viscoplastic characteristics. The shape and hardness of this mold can be controlled in real-time by the magnetic field. During polishing, the “polishing head” formed by the MR fluid generates shear forces in the contact area. By adjusting the rotation angle and speed of the workpiece, uniform material removal across the surface can be achieved, resulting in a smooth finish.

Compared to traditional processing methods, MRF can achieve high polishing efficiency by adjusting the magnetic field strength, which changes the shape and hardness of the solidified MR fluid. This allows for precise material removal from optical components factory without causing deformation due to stress changes, thereby avoiding the creation of subsurface damage layers and ensuring high surface quality. Additionally, since the polishing head formed by the MR fluid does not wear out, it ensures the continuity and integrity of the removal function.

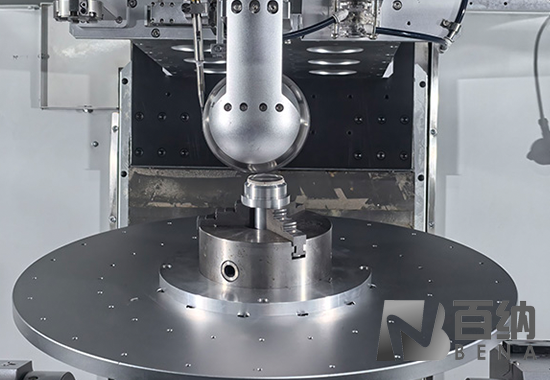

However, MRF is only suitable for convex surfaces with any radius of curvature. For concave surfaces, the radius of curvature must be larger than the radius of the polishing wheel. Currently, Bena Optics possesses internationally advanced MRF equipment capable of processing aspheric lenses with ultra-high precision and ultra-smooth surfaces.