Mirrors are critical optical components that enable light beam redirection, interference measurement, imaging, and illumination. These elements are typically made from polished glass or metal substrates, with reflective coatings applied to enhance their performance. The choice of coating material—such as aluminum, silver, or gold—determines the mirror's spectral response and durability.

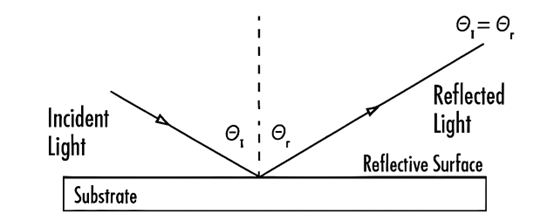

Flat mirrors are versatile optical tools widely used for beam deflection, interference measurement, and imaging system construction. Their surface flatness, often measured in fractions of a wavelength (e.g., λ/20), is crucial for minimizing light scattering and wavefront distortion. High-precision flat mirrors are essential for applications like laser interferometry, while cost-effective versions suit general-purpose optical setups.

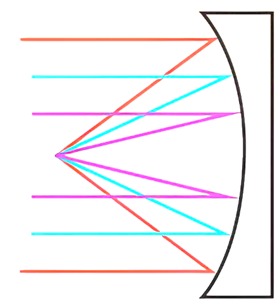

Concave mirrors are key components for beam focusing and light collection. They reflect parallel light rays to a precise focal point, making them ideal for laser systems, spectroscopy, and optical sensing. Aluminum and gold coatings optimize their performance across the UV to IR spectrum, ensuring stable and reliable optical solutions.

Cylindrical mirrors feature a one-dimensional curvature, enabling one-axis beam shaping and focusing. They are widely used in industrial laser cutting, optical spectroscopy, and defect detection, offering a balance of spectral compatibility and functional flexibility.

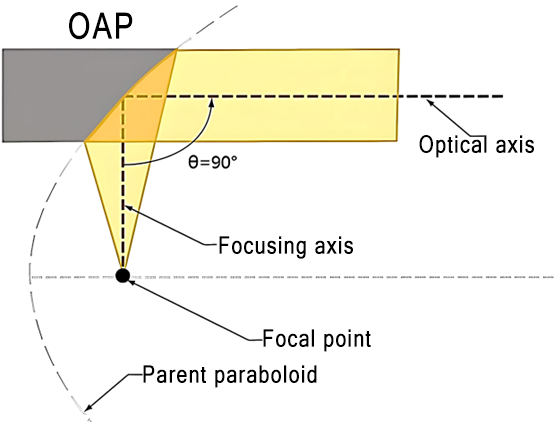

OAP mirrors provide aberration-free focusing of collimated light while separating the focal point from the optical path. Their reflective design eliminates phase delays and absorption losses, making them ideal for precise optical alignment in complex systems.

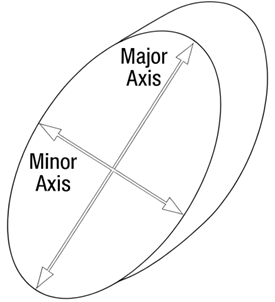

Elliptical mirrors utilize the geometric properties of ellipses to direct light from one focal point to another with high accuracy. They are crucial in laser resonators, multi-focus lighting systems, and high-energy laser applications, where precise focus control is essential.

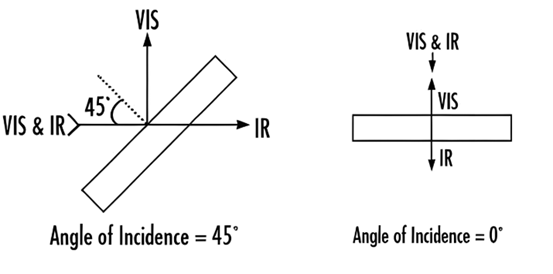

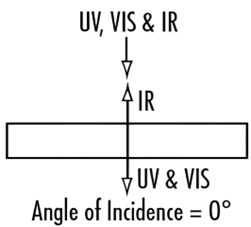

Cold mirrors selectively reflect visible light while transmitting infrared radiation, effectively managing system heat. They are widely used in high-power projectors and medical devices, where thermal management is critical for performance and longevity.

Hot mirrors function as the inverse of cold mirrors, reflecting infrared light while transmitting visible light. They are essential for applications requiring heat retention, such as infrared imaging and thermal analysis systems.

Mirrors are manufactured using polished glass or metal substrates, with reflective coatings applied to enhance performance. Common metal coatings include aluminum, silver, and gold, each offering unique spectral and durability advantages. For high-precision applications, multi-layer dielectric coatings provide superior reflectivity and wavelength specificity, though they are more sensitive to angle and wavelength variations.

Mirrors are indispensable components in modern optical systems, offering versatility, precision, and functionality across a wide range of applications. By understanding the unique properties and applications of flat, concave, cylindrical, parabolic, elliptical, cold, and hot mirrors, engineers and researchers can design systems that meet specific performance and thermal management requirements.