1. Dielectric Coated Mirrors

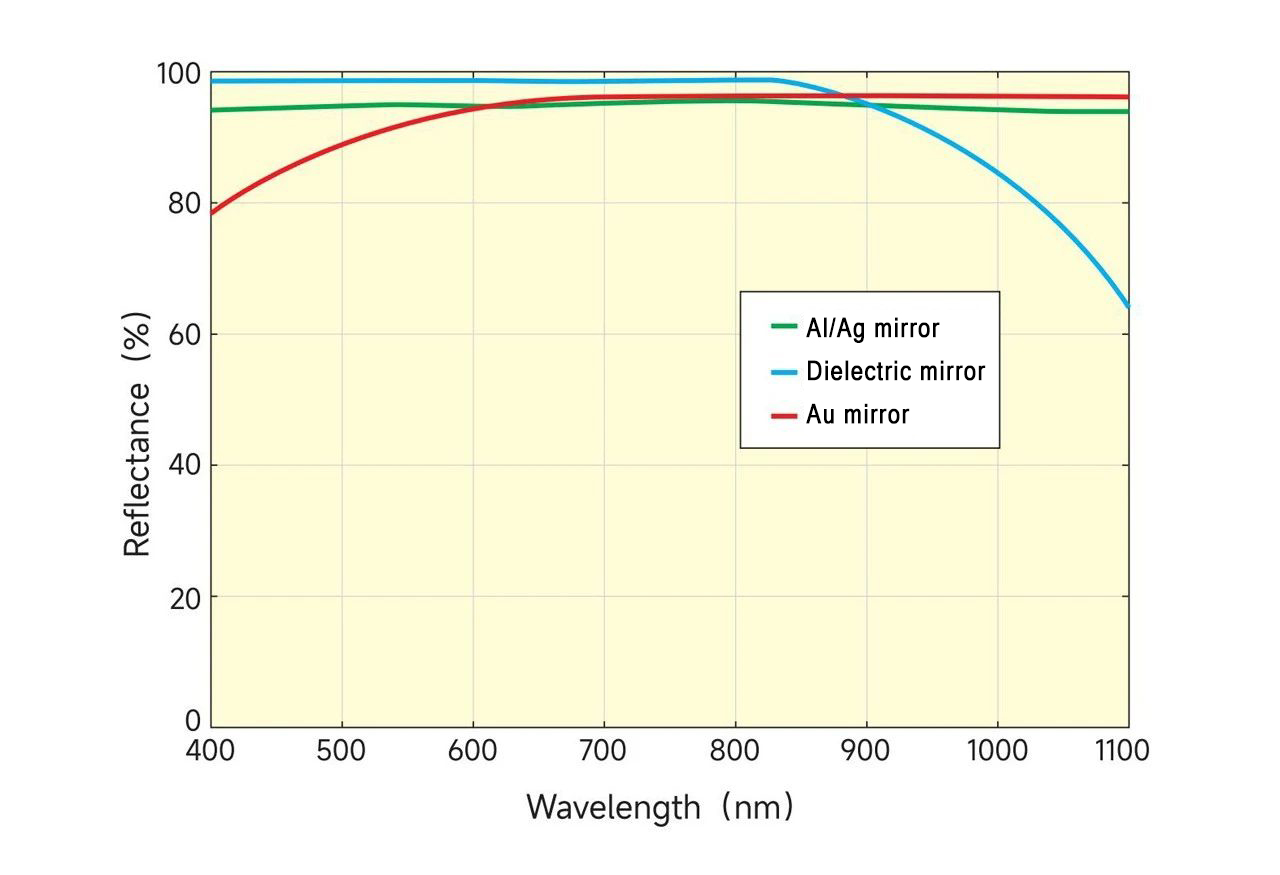

Dielectric coated mirrors feature multiple layers of dielectric coatings on optical components, enhancing reflectivity through interference superposition within a specific wavelength range. These mirrors offer high reflectance, are suitable for broad wavelength spectra, and do not absorb light, making them durable and suitable for multi-wavelength laser systems.

| Feature | Description |

|---|---|

| High Reflectance | Reflectance enhanced through interference superposition |

| Wide Wavelength Range | Suitable for broad spectral applications (e.g., visible to near-IR) |

| Durability | Hard coating resistant to scratches and environmental damage |

| Sensitivity | Highly angle-sensitive; requires precise alignment for optimal performance |

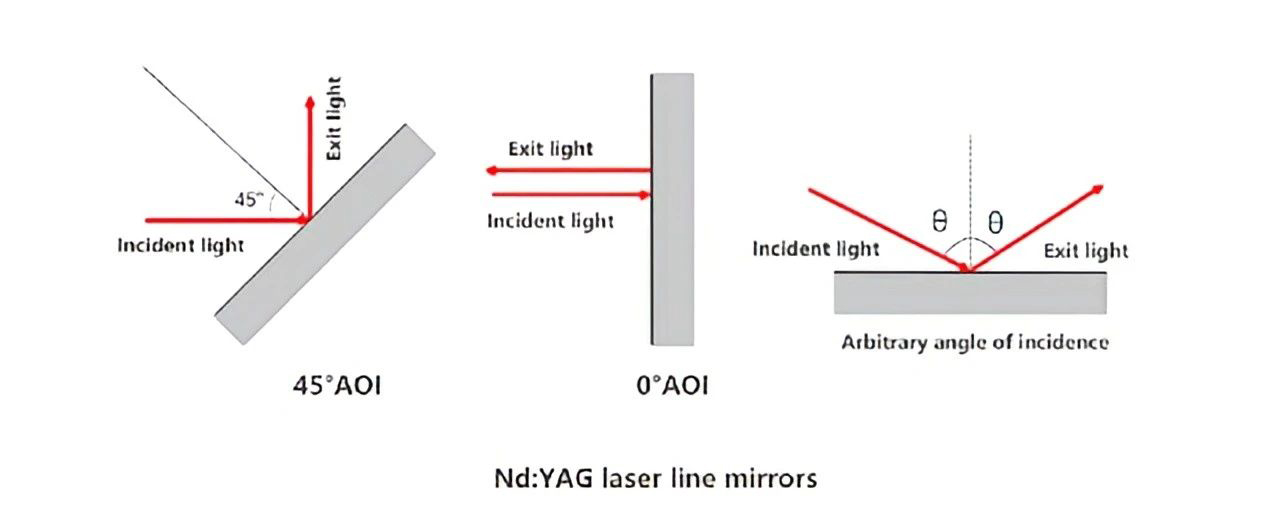

2. Laser Line Mirrors

Laser line mirrors are made from UV fused silica substrates with high-reflective Nd:YAG dielectric coatings, applied using electron beam evaporation and ion-assisted deposition techniques. Compared to K9 material, UV fused silica offers better homogeneity and a lower coefficient of thermal expansion, making it ideal for applications from the UV to near-infrared range, especially in high-power lasers and imaging.

| Parameter | Specification |

|---|---|

| Material | UV fused silica substrate |

| Coating | Nd:YAG dielectric coating |

| Applications | UV to near-IR, high-power lasers, imaging systems |

| Reflectance | >97% at 266 nm, 355 nm, 532 nm, 1064 nm |

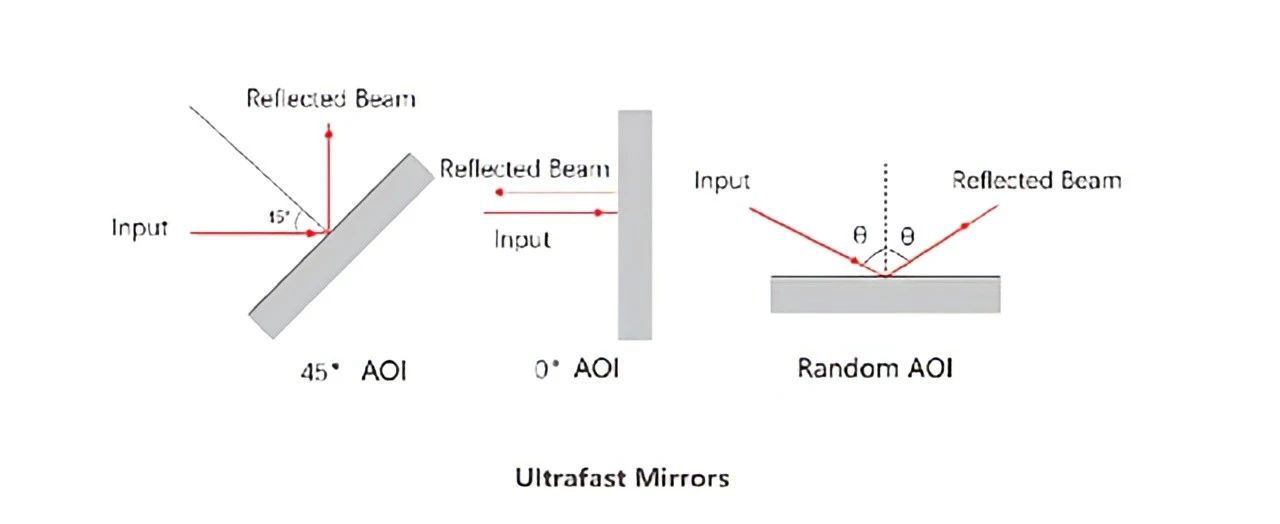

3. Ultrafast Mirrors

Ultrafast mirrors use fused silica substrates with low group delay dispersion (GDD) dielectric coatings, applied via ion beam sputtering (IBS). Fused silica's low thermal expansion and high thermal shock stability make it ideal for high-power femtosecond pulse lasers and imaging.

| Parameter | Specification |

|---|---|

| Material | Fused silica substrate |

| Coating | Low GDD dielectric coating |

| Applications | High-power femtosecond lasers, imaging systems |

| Reflectance | >99.5% at 460–590 nm, 700–930 nm, 970–1150 nm, 1400–1700 nm |

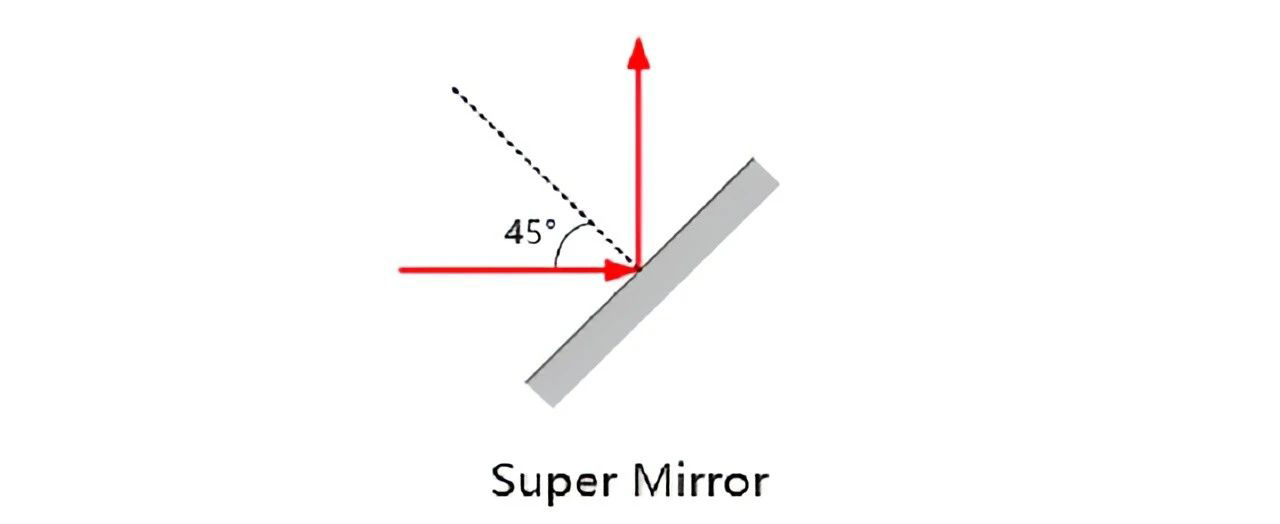

4. Super Mirrors

Super mirrors are created by depositing multiple layers of alternating high and low refractive index dielectric coatings on UV fused silica substrates. Increasing the number of layers enhances reflectance, allowing super mirrors to achieve reflectance above 99.99% at the design wavelength, making them ideal for high-precision optical systems.

| Parameter | Specification |

|---|---|

| Material | UV fused silica substrate |

| Coating | Multi-layer dielectric coating |

| Reflectance | >99.99% at design wavelength |

| Applications | High-precision optical systems requiring ultra-high reflectance |

5. Metal Coated Mirrors

Metal coated mirrors are highly effective for deflecting broadband light sources, offering high reflectance across a wide spectral range. However, metal coatings are prone to oxidation and discoloration in high-humidity environments. To protect the metal coating, a layer of silicon dioxide is applied to the surface, isolating the metal from direct air contact and preventing oxidation, which can affect optical performance.

| Parameter | Specification |

|---|---|

| Material | Metal coating with protective SiO₂ layer |

| Applications | Broadband light deflection |

| Durability | Requires oxidation protection |

| Reflectance | High across wide spectral range |

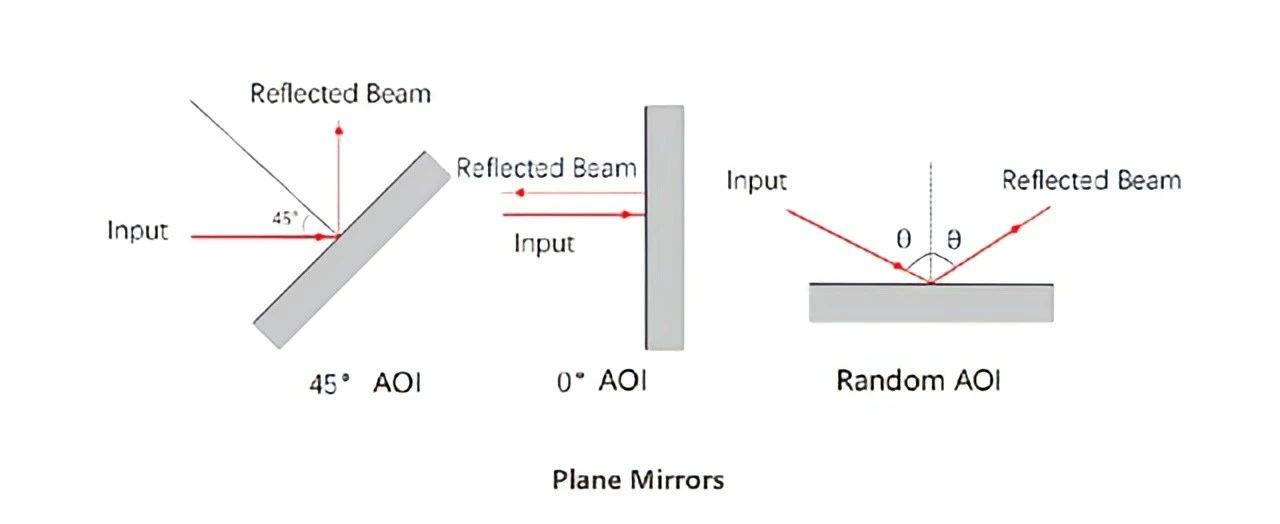

At Bena Optics, we offer a wide range of high-quality plane mirrors tailored to meet the specific needs of your optical systems. Whether you need dielectric mirrors for multi-wavelength applications, laser line mirrors for UV to near-IR ranges, ultrafast mirrors for high-power femtosecond lasers, super mirrors for ultra-high reflectance, or metal coated mirrors for broadband applications, Bena Optics has the perfect solution for you.

Visit our website to explore our full range of optical products and discover how we can help you achieve optimal performance in your optical systems.