At Bena Optics, we understand the critical role that the quality of optical products plays in our clients' projects. Therefore, we provide professional and reliable optical inspection services to ensure that every product undergoes rigorous testing and validation before delivery.

Advanced Inspection Equipment

Bena Optics' inspection laboratory is equipped with a range of high-precision optical inspection devices, including:

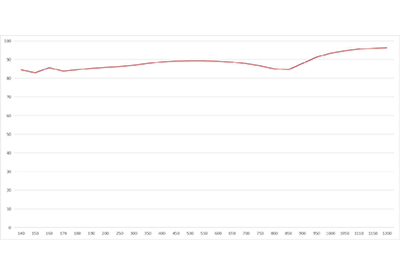

Spectrometers: Used for accurately measuring the transmittance, reflectance, and absorptance of materials, ensuring the performance of optical components meets the highest standards.

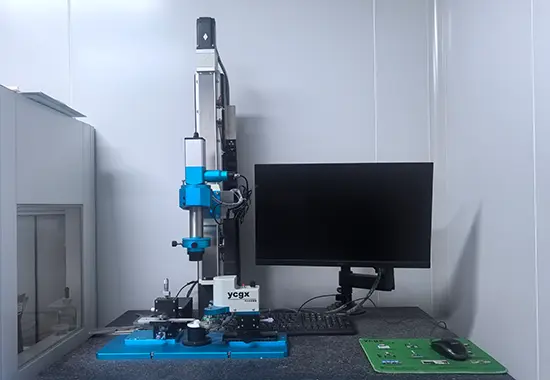

Microscopes: Providing high-magnification capabilities to thoroughly inspect the surface quality, scratches, and defects of products.

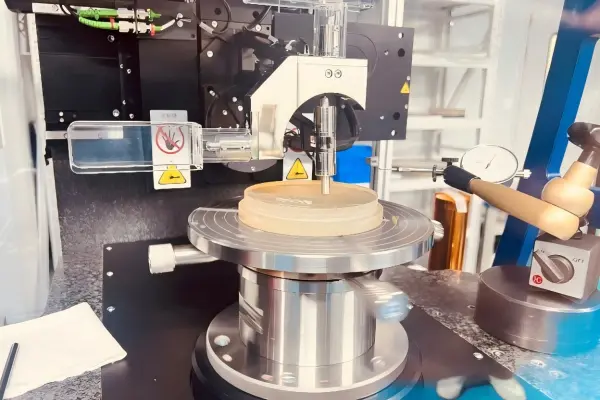

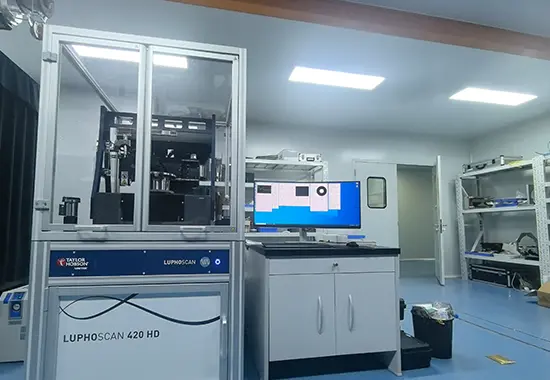

Automated Inspection Systems: Enabling efficient batch inspection to ensure consistency and reliability across all products.

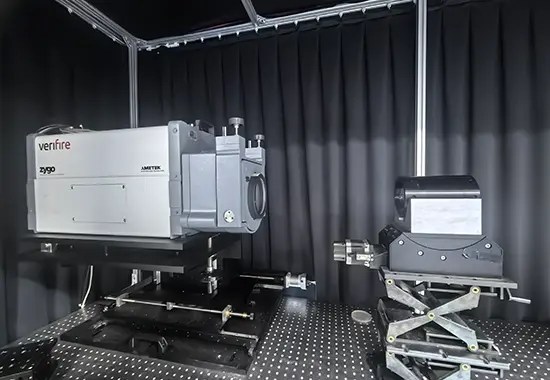

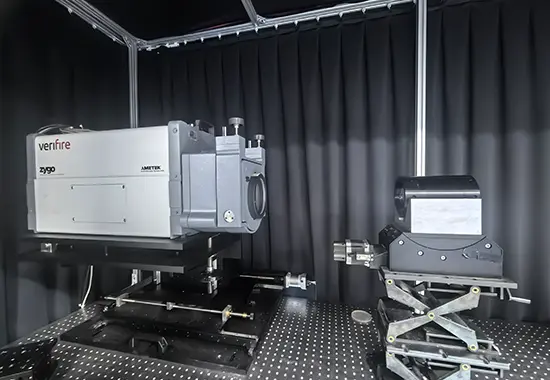

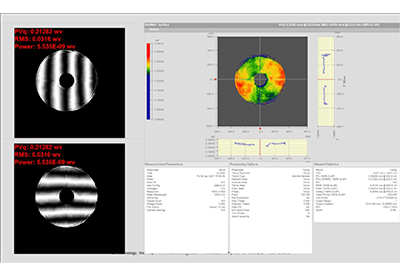

Laser interferometers: Used to measure the flatness and precision of optical surfaces, ensuring compliance with high-precision optical standards.

Bena Optics provides optical inspection services, including:

Optical Materials: Testing the refractive index of optical materials using a spectrometer. Surface Roughness: Profilm3D® optical profiler offers a fast, easy, and non-contact solution for 3D surface topography measurement.

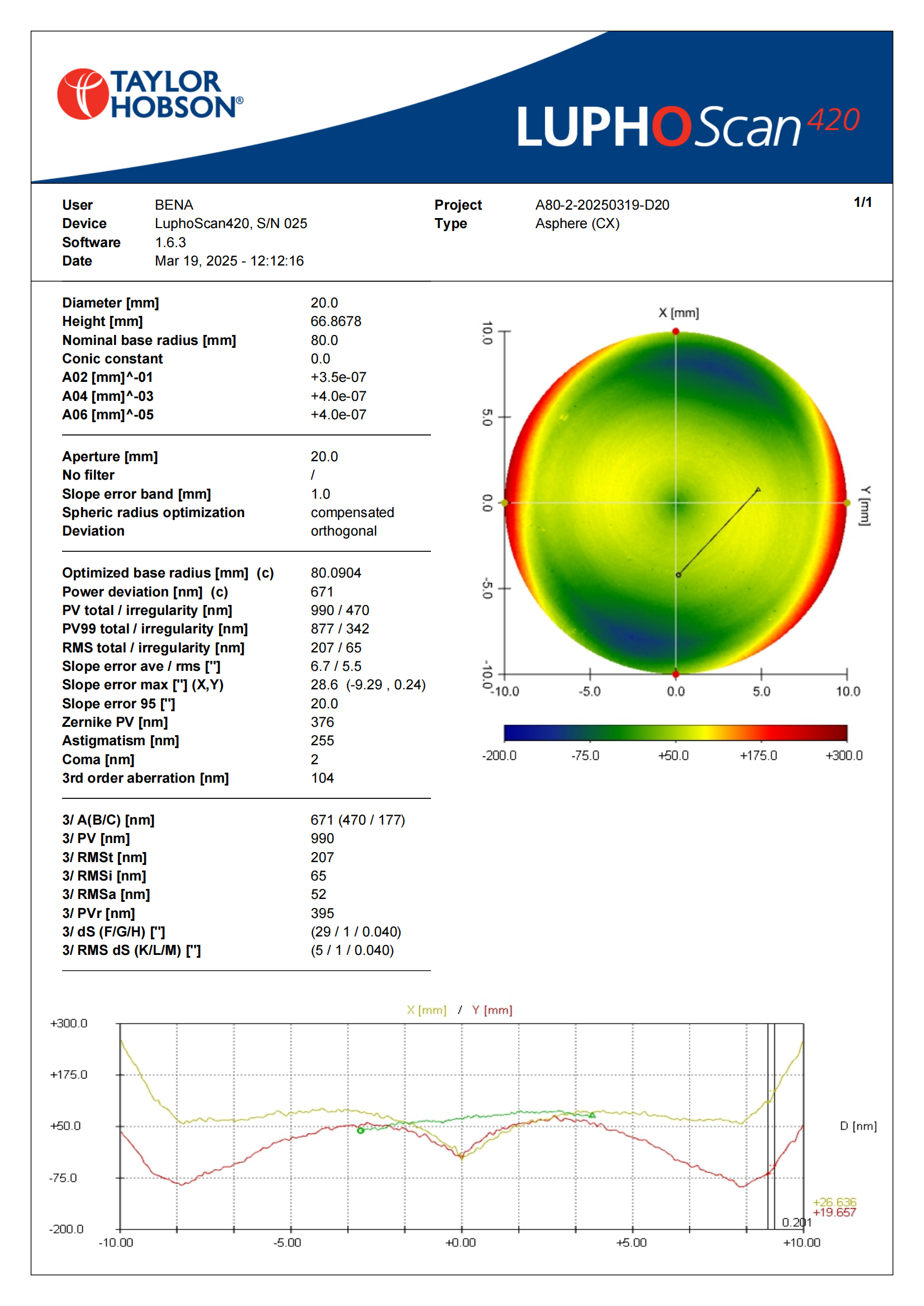

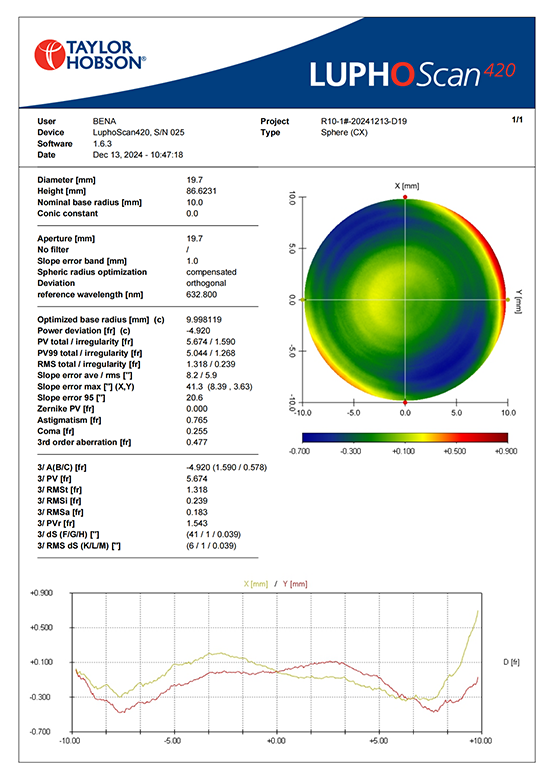

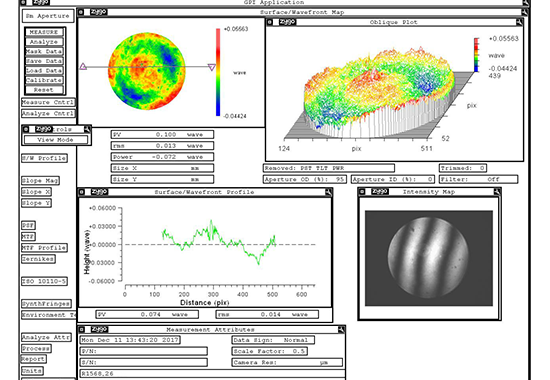

Surface Accuracy: Zygo laser interferometer.

Radius of Curvature: Zeiss coordinate measuring machine (CMM).

Coating: Hitachi UV4150 spectrophotometer.

Bena Optics can provide a comprehensive optical inspection report.

Multilayered Inspection Process

From the selection of raw materials to the final inspection of finished products, we have implemented a strict inspection process to ensure every production step adheres to international standards. The inspection process includes:

1. Raw Material Inspection: Preliminary testing of materials such as optical glass and plastics before production begins to ensure they meet performance requirements.

2. Production Process Monitoring: Real-time monitoring of key parameters such as machining accuracy and surface finish during production.

3. Comprehensive Finished Product Inspection:

1>Optical Performance Testing: Including transmittance, resolution, chromatic aberration, etc.

2>Physical Performance Testing: Such as wear resistance and impact resistance.

3>Environmental Adaptability Testing: Simulating performance under various environmental conditions (e.g., high temperature, low temperature, humidity).

Rapid Response and Report Generation

Our inspection team can complete tests in a short time and generate detailed inspection reports to help clients quickly understand the performance and status of the products. Reports include:

Inspection Data: Detailed measurement results and performance indicators.

Issue Analysis: If problems are identified during testing, we provide detailed analysis and improvement recommendations.

Product Rating: Rating products based on international standards to ensure clients have a clear understanding of the quality.