In the field of optics, aspherical processing technology shines like a brilliant gem, leading the new trend in optical component manufacturing with its unique advantages and wide applications.

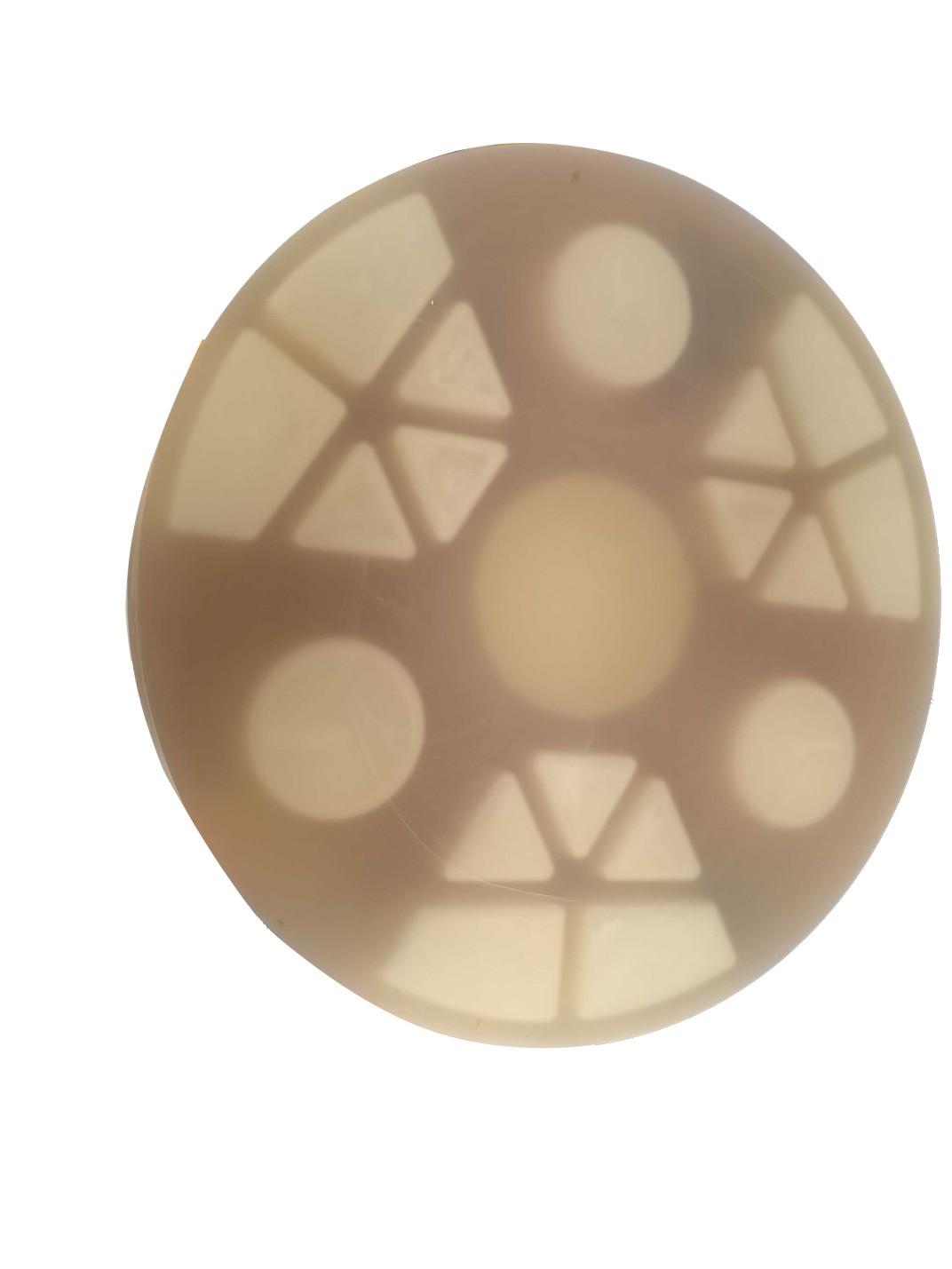

Aspherical lenses have a surface curvature radius that varies from the center to the edge, giving them several significant advantages in optical systems. Firstly, they can optimize optical performance, effectively reducing spherical aberration and controlling other higher-order aberrations, thereby greatly improving beam focusing and imaging light collection efficiency. Because of this, aspherical devices are widely used in many fields. For example, in smartphone cameras, they allow us to take clearer, high-quality photos; in laser beam shaping, they enable more precise laser control; in lithographic objectives, they help improve lithographic precision; and they play a key role in night vision optics, among other applications.

However, aspherical processing is not easy and presents many challenges. The complex shape, with varying curvature at different points, makes it difficult for the polishing mold to perfectly match the processing surface, leading to challenges in surface correction. Additionally, the tilt of the aspherical surface relative to another plane or spherical surface cannot be corrected by edge grinding, making it difficult to ensure the coaxiality of the optical surface. Furthermore, traditional spherical inspection methods cannot be used for aspherical surfaces, requiring specialized auxiliary equipment.

In the field of aspherical processing, Bena Optics has become an industry leader with its outstanding capabilities and innovative spirit.

Bena Optics brings together professional talents from top domestic and international universities and research institutions. Team members have deep theoretical knowledge and rich practical experience in optical design, ultra-precision processing, and materials science.

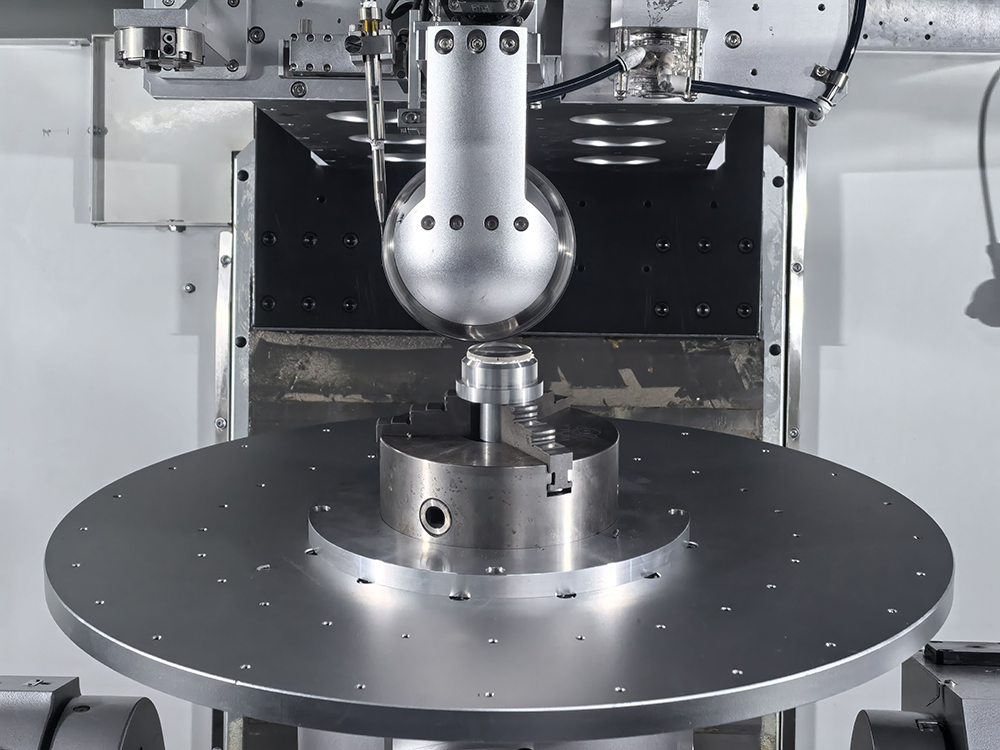

The company’s nano-processing center is equipped with a series of internationally leading ultra-precision optical product processing and testing equipment. It can achieve high-precision turning of complex freeform surfaces, linear diffraction surfaces, and optical prismatic structures, with surface shape accuracy (P-V) reaching 0.15 microns and surface roughness (Ra) as low as 3.0 nanometers.

In aspherical processing, Bena Optics possesses several leading technologies. Firstly, the advanced single-point diamond turning technology, through precise control of computer processing parameters, directly uses diamond tools for single-point turning to produce aspherical optical parts that meet optical quality requirements. This technology is suitable for processing small to medium-sized, medium-batch optical parts, with high production efficiency, high processing accuracy, and good repeatability. The processed optical parts under 120mm have a surface shape accuracy of 1/21λ and a surface roughness RMS value of 0.02-0.06mm.

Additionally, Bena Optics has globally leading technology in hard steel optical mold core processing. It is the first to apply ultrasonic ultra-precision single-point diamond turning technology to directly cut hard steel, achieving nanometer-level precision and leading the world. This technology eliminates the need for nickel plating, avoiding issues such as the easy detachment of the nickel layer, while providing higher surface quality and dimensional accuracy, with surface roughness Ra<7nm and shape accuracy < 0.2μm. This not only greatly enhances the performance and reliability of optical mold cores, but also extends the injection molding life of the mold core by three times compared to nickel-plated mold cores, reaching hundreds of thousands of molding cycles. It significantly reduces production costs, improves production efficiency, and shortens the processing cycle by four weeks.

At the same time, the company’s self-developed error compensation algorithm is also one of its core competencies. This algorithm accurately measures and analyzes the surface shape accuracy of lenses after injection molding, calculates the error distribution equation, and synthesizes a new surface with the original design equation. By recompiling the NC program, it achieves dynamic adjustments to the processing process, thereby greatly improving product accuracy and consistency.

In practical applications, Bena Optics’ products are widely used in various fields. For example, in smartphone camera lenses, their optical mold cores and lenses provide crucial support for high-definition photography; in laser mice, they ensure precise positioning and sensitive operation; and in the biomedical field, they provide strong support for the imaging and diagnostic functions of medical devices.

In summary, Bena Optics has demonstrated outstanding technical strength and innovation capabilities in the field of aspherical processing.