1. Turn on the computer and monitor

Input: User name: zygo

Password: None

Login to the operating system

2. Turn on the power of the interferometer host, and warm up the interferometer for 15~20 minutes to make it work stably.

3. Double click the MetroPro icon on the desktop of the computer to enter the MetroPro measurement software.

Turn on the power switch and the indicator light will be on.

1. Left mouse button click on the corresponding measurement application icon to open the test application.

For example: open GPI.app

2. Construct the test optical path (including the standard mirror and sample), adjust the interference fringes, and refer to the specific measurement method in the back.

Set up the test optical path (including standard mirror and sample) and adjust the interference fringes. Set up the necessary measurement parameters in MetroPro software, refer to the MetroPro software manual.

3. Click the Measure button in the software or press the F1 key on the keyboard to complete the measurement and display the results.

4. Save the test report. Click the “zygo” symbol with the left mouse button to print or save the window image.

5. Click the Save Data button in the software to save the test data.

1. Close the MetroPro software

Click the X button on the upper right corner of MetroPro, a dialog box will pop up, click YES to close the MetroPro software.

2. Shut down the main unit of the interferometer

Turn off the power switch of the main unit, and the indicator light will go out.

3. Turn off the computer and monitor.

Install the transmission element

Warning!

Do not touch the transmissive element with your hands during the following steps. Fingerprints can permanently damage the optical

coating and the surface of the optics.

1. Remove the transmissive element from its protective case by grasping the metal edge of the element.

2. Align the two metal tabs on the edge of the transmissive element with the two corresponding slots on the main unit's adjustment bracket.

WARNING!

When the system is installed in a vertical configuration, do not let go of the transmissive element until it has been locked in place by following the steps below.

3. Gently snap the transmissive element into the mainframe adjustment bracket, holding the metal edges of the group element in place with your hand. Turn the black locking knob

Turn the black locking knob in a clockwise direction, which will secure the unit to the adjustment bracket.

NOTE: When it is time to remove the unit from the adjustment bracket, hold the unit by hand from the metal edge of the unit while turning the locking knob in a counterclockwise direction.

When it is time to remove the module from the adjustment bracket, hold the module by hand from the metal frame of the module and loosen the fastening screws counterclockwise.

Before you can make measurements with the interferometer, you must align the transmissive element with the interferometer and then align the measurement sample with the transmissive element.

Then align the measurement sample with the transmissive element. How to align the transmissive element is described below. Calibrating the measurement sample is described in detail in “Measuring surface quality”.

Measuring the Surface Quality” and ‘Measuring the Transmitted Wavefront Quality’.

1. Confirm that the light bar switch is in the ON position. (Make sure the light bar switch is in the ON position.)

2. Press the ALIGN/VIEW button on the remote control. The calibrated target crosshair and one or more bright dots will be displayed on the monitor.

on the monitor. The brightest point represents the light reflection from the outermost surface of the transmissive element.

The sample to be measured is calibrated with the transmissive element. After the sample has been calibrated, measurement is simply a matter of pressing a Measure key in the MetroPro software. Whether the interferometer is placed vertically or horizontally, it is generally accepted that the measurement cavity (or sample-to-standard mirror distance) should be made as large as possible.

distance from the sample to the standard mirror) as short as possible. This will minimize the distortion of the measured wavefront by air flow.

Mounting the Transmission Flat (TF) reference mirror: Place the two metal pins on the lens into the slides on the adjustment frame of the interferometer.

1. Slide the two metal pins on the lens into the slots on the adjustment bracket of the interferometer, hold the metal frame of the lens and rotate the lens clockwise, then tighten the locking knob on the side.

Then tighten the locking knob on the side.

2. Align the standard lens: Press the ALIGN/VIEW button of the remote control to switch the display screen to ALIGN state, and the image of the cross-hair filament appears in the plane. Adjust the two knobs on the adjustment bracket of the interferometer main unit until the brightest point of light on the screen is in the center of the cross filament. 3.

3. Place the sample to be measured on the measurement adjustment frame: adjust the adjustment frame tilt knob until the bright point of the measured part on the screen is also in the center of the cross-hairline, coinciding with the reflected light point of the lens.

4. Press the ALIGN/VIEW button of the remote control again to switch the display screen to “View”, and the interference fringes should appear on the screen. Press the ZOOM button to zoom in and out so that the image of the surface you want to measure fills the screen as much as possible. 5.

5. Place a piece of paper or other marker as close as possible to the part to be measured, this will provide a distinct edge for focusing. Press the FOCUS button on the remote control to focus, making the image edge to edge, and focus to make it edge to edge.

6. Fine tune the tilt adjustment knob of the sample adjustment rack to zero out the fringes (so that interference fringes are minimized).

7. Press the MEASURE key on the MetroPro or the F1 key on the keyboard to perform the measurement.

1. Do not touch the main unit or the anti-vibration platform during measurement.

2. In order to minimize the risk of electric shock, the instrument must be well electrically grounded through the power supply output.

3, in the interferometer manual to read about the laser safety instructions.

4. Do not move the main unit. If it is necessary to move, please use the two special handles designed on the top of the instrument to

If it is necessary to move, please use the two special handles designed on the top of the instrument to move it carefully, and do not touch the piezoelectric ceramics directly with your hands to move it by force.

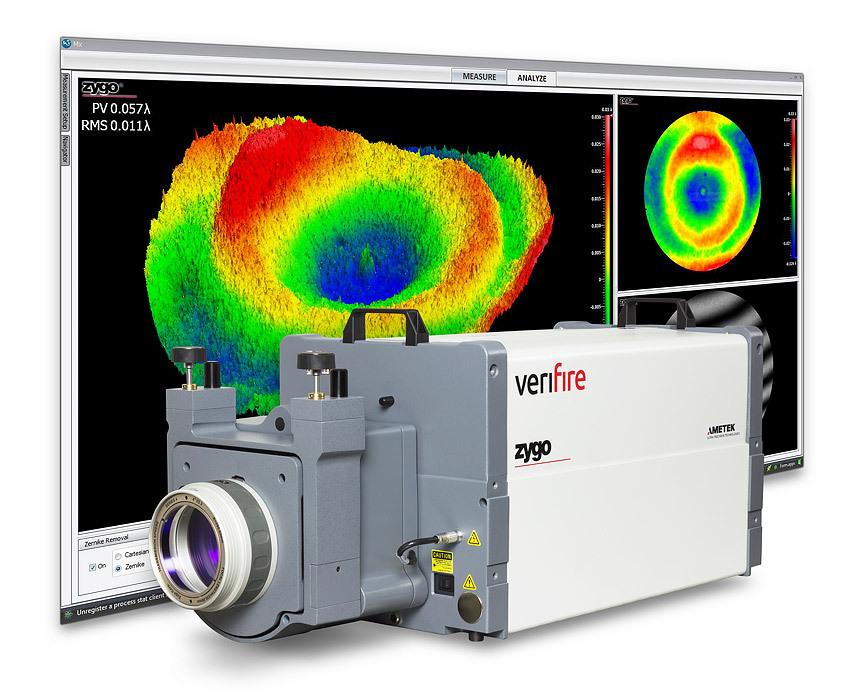

The piezoelectric ceramic is a high-precision structure, easy to be damaged by the force, so avoid external force on it at any time. As shown in the figure:

Maintenance of the host

The main unit is practically maintenance free, however, it is very important to operate the instrument in a relatively clean environment.

However, it is very important to operate the instrument in a relatively clean environment. If you need to clean the main unit housing, follow the steps below.

1. Using a furniture cleaner of moderate pH, wipe off fingerprints and dust from the sides and front panel of the main unit with a soft cloth moistened with a small amount of cleaner.

panel, such as fingerprints and dust.

2. Use a dry cloth to clean dust from the components. Do not use cleaners or sprays near the optics.

The lens is a coated optic and cleaning sprays may damage the surface. For the section on cleaning the lens system, see

“Cleaning the Optics” section in the following chapter.

Refer to the manufacturer's documentation for maintenance of components including the computer, color monitor, mouse, keyboard, and printer (if installed).

The components to be serviced include the computer, color monitor, mouse, keyboard, and printer (if installed).

If you are experiencing problems and are unable to locate the problem, contact Zygo.

When the interferometer is not used for a long period of time after completing a measurement, carefully remove the lens and other optics and store them in a special lens case.

store them in the special lens case.

Cleaning of any precision optics may damage the surface. All cleanable lens surfaces are coated.

All cleanable lens surfaces are coated. Unnecessary and incorrect cleaning can easily damage the coating. We should hold our optics properly and keep them out of the way when not in use.

components correctly, return them to their plastic cases when not in use, and maintain a clean environment to minimize the number of cleaning cycles.

The number of cleanings should be minimized.

Do not attempt to clean the optics inside the main unit as this will affect system performance. Contact Zygo if necessary.

Contact Zygo if necessary.

Polyethylene lab gloves

Wear gloves to prevent contamination of the device surfaces and to protect your skin from contact with harmful and irritating chemical substances.

substances.

Compressed gas with nozzle

Compressed gas with a nozzle is used to blow away dust and dirt from the surface of the optics.

Mirror Paper

Used to clean the surface of the optics when necessary. Mirror paper should be specialized for wiping precision optics.

Cotton swabs

Used to clean hard-to-reach surfaces, cotton swabs should be made of wood and paper, cotton and other materials. Plastic rods dissolve in acetone

Plastic rods will dissolve in acetone.

Solvents

Use spectral grade isopropyl alcohol and methanol to clean contaminants adhering to optical surfaces. Use a neutral 1% soap solution or optical cleaner.

concentration soap solution or optical cleaner to clean oil-based contaminants.

Warning!

Care must be taken when using isopropyl ethanol and methanol; they are flammable and toxic. Do not reuse cleaning wipes; reuse can cause dirt to adhere and damage the optics.

Before cleaning the optics, remove jewelry such as rings from fingers and wrists, wash your hands carefully to remove skin oils, and wear gloves.

Dust or fine contamination

1. Blow off any loose, small bits of dust or contamination with the nozzle.

2. If dust is still present, wrap two sheets of mirror paper around a wooden swab or fold a sheet of mirror paper so that it is just wider than the part to be cleaned.

3. Place a drop of ethanol or methanol on the paper.

4. Wipe the lens with it once in one direction. If more wiping is needed, use a new wooden swab and mirror paper. Fingerprints, Oil and Water Marks NOTE: This condition must be cleaned from the surface immediately. Acids on the skin can damage the lens surface.

5. Blow off any small loose dust or dirt with a spray nozzle.

6. If dirt is still present, wrap two sheets of mirror paper around a wooden stick or fold a sheet of mirror paper so that it is just wider than the part to be cleaned.

7. Apply a drop of 1% soap solution to the paper.

8. Wipe the lens once in one direction. If more wiping is needed, use a new swab and paper.

9. Repeat steps 2 to 4 using the paper moistened with distilled water. in order to wipe away any soap residue.

10. Moisten the paper with methanol or ethanol and repeat steps 2 to 4.