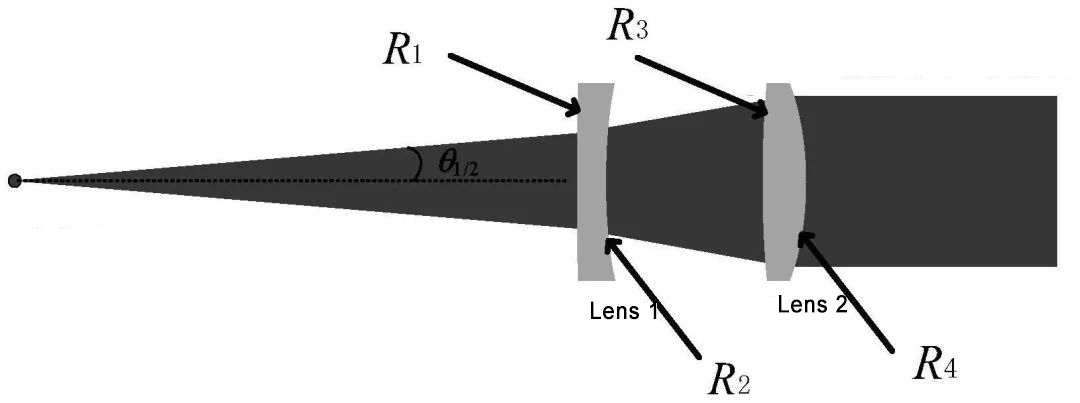

Laser collimators primarily rely on the principles of geometrical optics, specifically the refraction and reflection laws governing lenses or mirrors. When a laser beam enters a collimator, a lens system utilizes a combination of lenses with different curvatures.

For example, convex lenses converge light rays, while concave lenses diverge them. By carefully designing the focal lengths and spacing of convex and concave lenses, a laser beam with a certain divergence angle can be transformed into a parallel beam after passing through the lens assembly.

In mirror systems, parabolic mirrors are commonly used. According to the optical properties of a parabola, light rays emanating from the focal point of a parabolic mirror will reflect and exit parallel to the symmetry axis. Therefore, placing the laser source at the focal point of a parabolic mirror can produce a parallel laser beam.

Lasers possess characteristics such as coherence, monochromaticity, and directionality. During the collimation process, the wavefront properties of the laser must be considered. The design of the collimator should ensure minimal distortion of the laser wavefront.

The interference principle of light waves can be used to test and optimize the performance of the collimator. For instance, an interferometer can measure the difference between the laser wavefront after passing through the collimator and an ideal plane wave, thereby allowing further improvements in the design and manufacturing process of the collimator.

The primary function is to transform a laser beam with a certain divergence angle into a parallel beam. This allows the laser to maintain a small spot size and high energy density over a longer propagation distance.

For example, in long-distance laser communication or laser ranging applications, a collimated laser beam can reduce energy loss during propagation, thereby increasing the transmission distance and accuracy of the signal.

In addition to collimation, the shape of the laser beam can be adjusted to some extent. For instance, a circular laser spot can be shaped into a square or elliptical spot to meet the requirements of different application scenarios.

In laser processing, different spot shapes can result in different processing effects. By using a collimator for beam shaping, the processing technique can be optimized.

Precisely controlling the energy distribution of the laser beam. Through the design and optimization of the collimator, the laser energy can be uniformly distributed or distributed according to a specific pattern in the collimated beam.

In applications requiring high uniformity of laser energy, such as laser annealing and laser thin-film deposition in semiconductor manufacturing processes, this energy control function is crucial.

Bena Optics is dedicated to the design and manufacturing of optical lenses, including system design, assembly, and debugging, offering comprehensive process management. It is the optimal choice for optical imaging.