Bena Optics specializes in processing all kinds of high-precision mirrors, diverse substrates and thin film coatings.

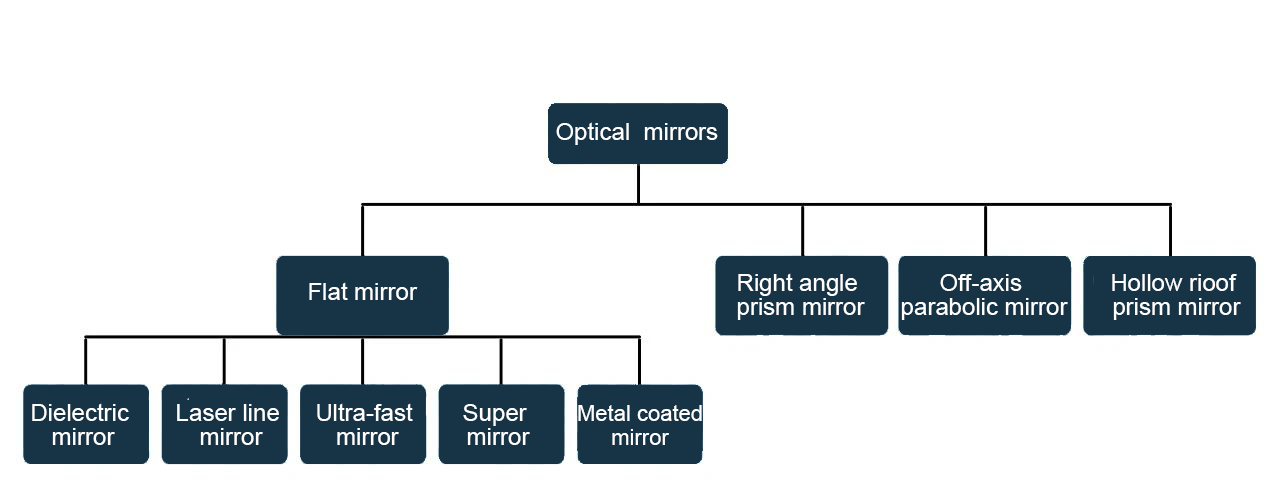

The Flat / plane mirrors

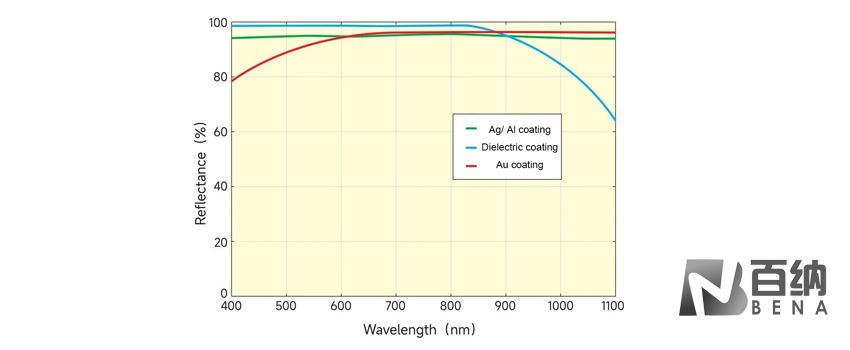

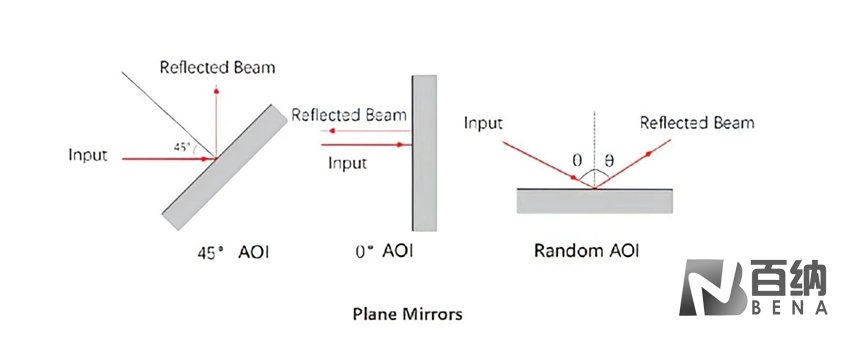

1, Dielectric Coated Mirror: Multiple layers of dielectric coatings are deposited on the surface of optical components, causing interference and superposition within a specific wavelength range to enhance reflectivity. These mirrors have high reflectivity, can be used over a broad spectral range, do not absorb light, are hard and resistant to damage, making them suitable for multi-wavelength laser optical systems. However, the coating layers of this type of mirror are thicker, angle-sensitive, and relatively expensive.

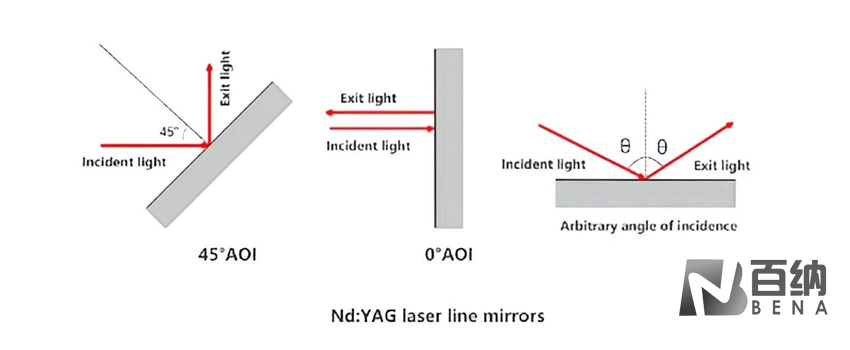

2, Laser Line Mirror: The substrate material of the laser line mirror is UV-grade fused silica, with a high-reflectivity coating of Nd:YAG dielectric applied through electron beam evaporation and ion-assisted deposition. Compared to K9 material, UV-grade fused silica offers better uniformity and a lower coefficient of thermal expansion, making it particularly suitable for applications in the ultraviolet to near-infrared wavelengths, high-power lasers, and imaging fields. Common working wavelengths for laser line mirrors include 266 nm, 355 nm, 532 nm, and 1064 nm, with incident angles of either 0-45° or 45°, and reflectivity exceeding 97%.

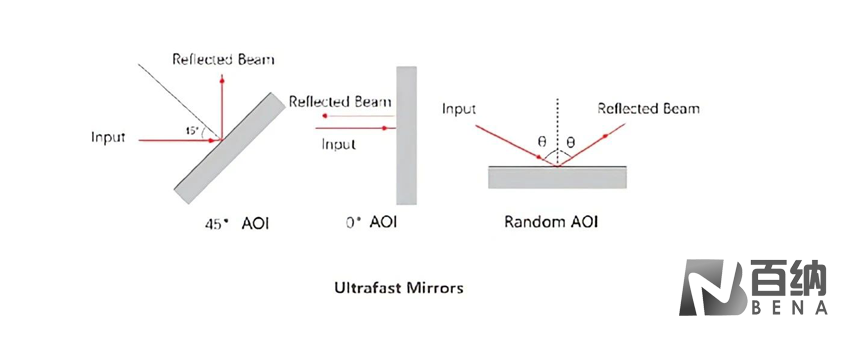

3. Ultra-Fast Mirror: The substrate material of the Ultra-Fast Mirror is fused silica, with a high-reflectivity coating of low group delay dispersion dielectric applied using the ion beam sputtering (IBS) process. Fused silica features a lower coefficient of thermal expansion and exceptionally high thermal shock stability, making it particularly suitable for high-power femtosecond laser systems and imaging applications. The mirror is commonly used in the following wavelength ranges: 460 nm-590 nm, 700 nm-930 nm, 970 nm-1150 nm, and 1400 nm-1700 nm, with the light beam incident at 45°, achieving reflectivity greater than 99.5%.

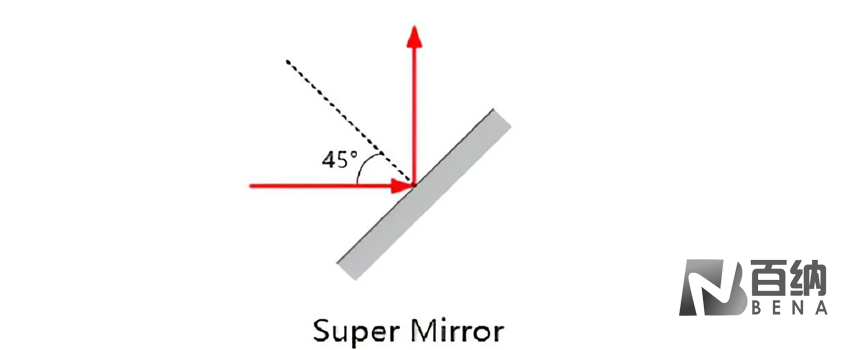

4, Super Mirror: The super mirror is fabricated by depositing multiple alternating layers of dielectric coatings with varying refractive indices on a UV-grade fused silica substrate. By increasing the number of coating layers, the reflectivity is enhanced, allowing the super mirror to achieve a reflectivity of better than 99.99% at the designed wavelength. This makes it highly suitable for optical systems where extremely high reflectivity is required.

5, Metal-Coated Mirror: Metal-coated mirrors are highly suitable for deflecting light from broadband light sources, as they exhibit high reflectivity across a wide spectral range. Metal coatings are prone to oxidation, discoloration, or even peeling in high-humidity environments. Therefore, metal-coated mirrors typically have a layer of silica deposited on their surface to create a barrier between the metal coating and the air, preventing oxidation and maintaining the mirror's optical performance.