In the field of precision optics, front-surface optical mirrors stand out for their superior reflectivity and low distortion, making them a core component of many high-end optical systems. As a global leading manufacturer of optical components, Bena Optics is committed to providing high-performance front-surface mirrors that cater to a wide range of applications, from consumer electronics to cutting-edge research.

I. Definition and Core Principles

Front-surface optical mirrors are optical components that use vacuum coating technology to apply a metal silver or aluminum film on the front surface of optical glass. Their core principle involves reflecting light directly using the first surface, avoiding image distortion and ghosting caused by back-surface reflection in traditional mirrors. Compared to traditional mirrors, front-surface mirrors enhance reflectivity (averaging over 94% in the visible light spectrum, with some premium products reaching 99%) and significantly reduce light energy loss by directly exposing the coated surface to incident light.

II. Structure and Material Characteristics

Base Material Selection

Bena Optics' front-surface mirrors use high-quality float glass and fused silica as base materials. Fused silica, with its low thermal expansion coefficient and high surface flatness (reaching λ/20), is an ideal choice for high-precision optical systems. The thickness of the mirrors ranges from 0.5mm to 5.0mm, with customizable sizes to meet diverse application needs.

Coating Technology

Our coating materials include aluminum films (reflectivity over 94%) and silver films (higher reflectivity but prone to oxidation). Some premium products feature dielectric coatings (such as titanium dioxide and silicon dioxide) to enhance durability and resistance to contamination. Our coating processes undergo rigorous abrasion resistance, moisture resistance, and salt spray tests to ensure stable performance in extreme environments, meeting the demands of various complex optical systems.

III. Key Performance Parameters

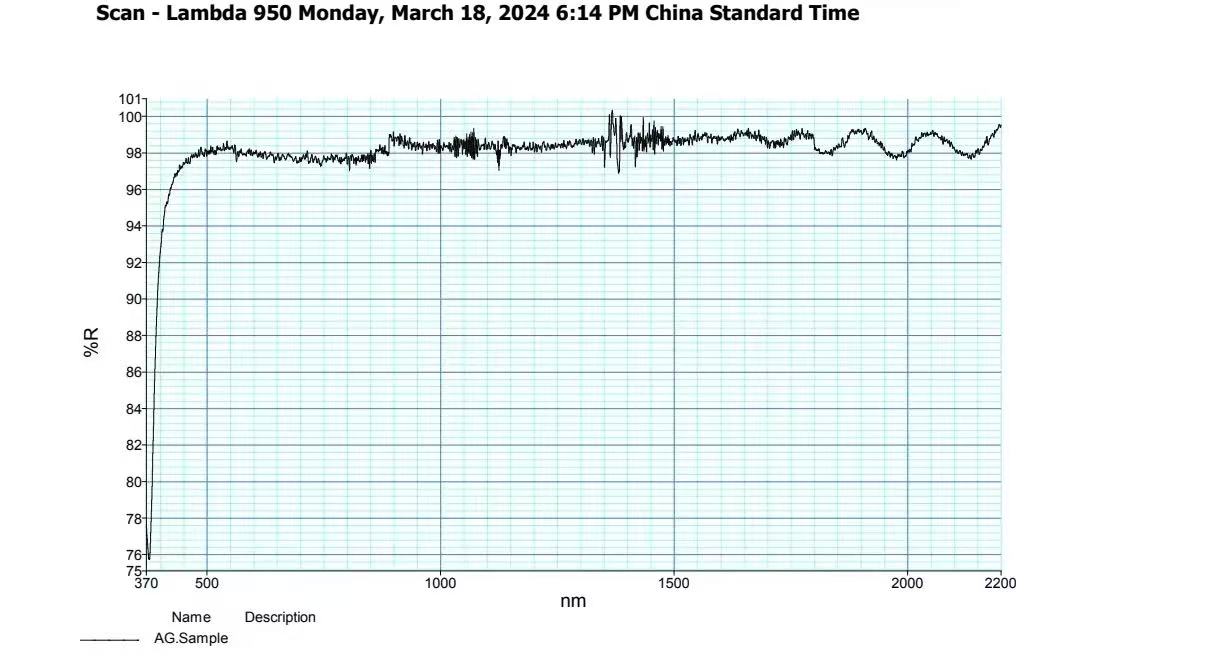

Reflectivity

Visible light spectrum (400-700nm) average reflectivity ≥94%, with certain specific wavelengths (such as 450nm blue light) reaching 95.5%.

Infrared mirrors (e.g., HR-780 series) achieve reflectivity ≥97% at 780nm, making them ideal for laser printers and infrared devices.

Surface Accuracy

Standard products have a wavefront error ≤λ/4, with high-precision models reaching λ/20 (e.g., Bena Optics #34-354).

Environmental Adaptability

Operating temperature range: -40°C to +80°C. The coating features a hydrophobic layer to effectively reduce dust accumulation, ensuring stable operation in harsh environments.

IV. Applications

Consumer Electronics and Office Equipment

Bena Optics' front-surface mirrors are widely used in scanners, projectors (e.g., LCD projectors), and copiers to ensure high-fidelity imaging and avoid image ghosting. In laser printers (LBP), infrared mirrors significantly enhance the positioning accuracy of laser beams, ensuring consistent print quality.

Industrial and Research Applications

Semiconductor Manufacturing: In lithography machines, our front-surface mirrors are used for beam focusing, significantly improving chip manufacturing yield.

Medical Devices: Reducing image distortion in endoscopes and microscopes supports precise diagnostics.

Astronomy: Large telescope primary mirrors use front-surface mirrors to effectively reduce atmospheric refraction interference.

New Energy and Security

Solar Concentrators: High-reflectivity mirrors improve the efficiency of solar energy conversion.

Infrared Night Vision and Radar Systems: Enhancing signal reception sensitivity improves system performance.

Bena Optics' front-surface optical mirrors, with their high reflectivity, low distortion, and high precision, are the perfect choice for precision optical systems. From consumer electronics to cutting-edge research, our products demonstrate exceptional performance and reliability across various fields. With continuous technological advancements (such as dielectric coatings and AI coating processes), we will continue to lead innovation in the optical component industry, delivering higher performance and lower-cost solutions to our customers.